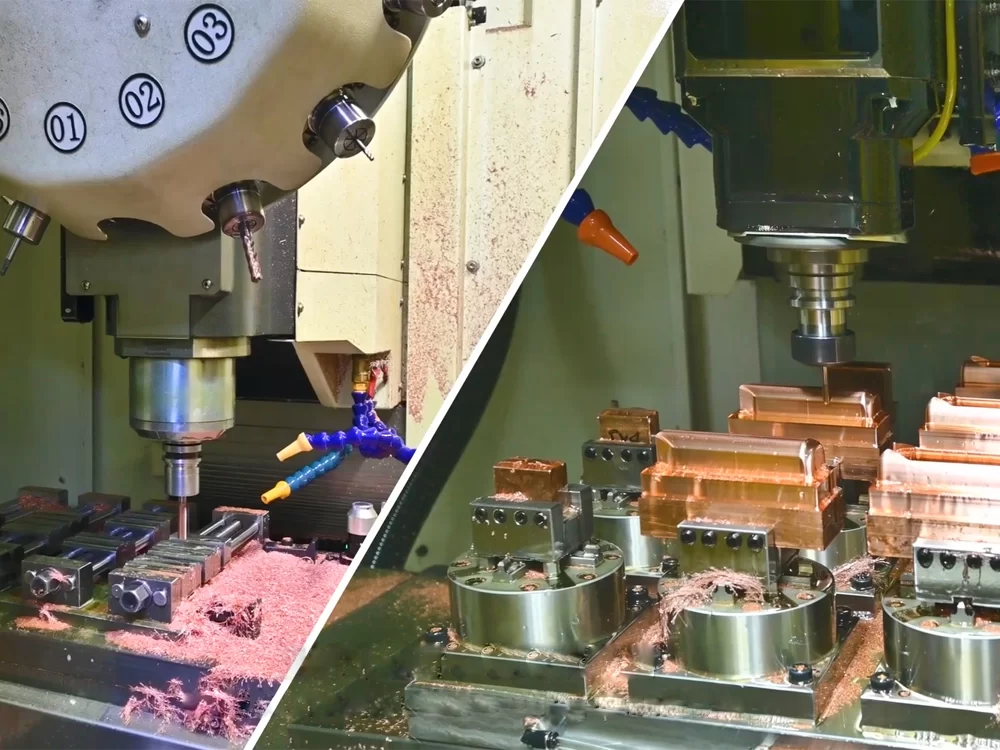

Weld lines are the most common defects in injection molded products. Except for a few injection molded parts with very simple geometric shapes, they occur on most injection molded parts (usually in the shape of a line or a V-shaped groove), especially large and complex products that require multi-gate molds and inserts.

Weld lines not only affect the appearance quality of plastic parts, but also affect the mechanical properties of plastic parts, such as impact strength, tensile strength, elongation at break, etc. to varying degrees. In addition, weld lines also have a serious impact on product design and the life of plastic parts. Therefore, they should be avoided or improved as much as possible.

The main reasons for weld marks are: when the molten plastic encounters inserts, holes, areas with discontinuous flow rates or areas where the filling material flow is interrupted in the cavity, multiple melts converge; when the gate injection filling occurs, the material cannot be completely fused.

Causes and solutions for weld marks:

1. The temperature is too low

The diversion and convergence performance of low-temperature melts is poor, and weld marks are easily formed. If weld fine lines appear on the inner and outer surfaces of the plastic part at the same location, it is often due to poor welding caused by too low material temperature. In this regard, the barrel and nozzle temperature can be appropriately increased or the injection cycle can be extended to promote the material temperature to rise. At the same time, the amount of cooling water passing through the mold should be controlled, and the mold temperature should be appropriately increased.

In general, the strength of the weld mark of the plastic part is poor. If the corresponding part of the mold where the weld mark is generated is locally heated and the local temperature of the welded part of the molded part is increased, the strength of the welded part of the plastic part can often be improved.

If the low-temperature molding process must be used due to special needs, the injection speed and injection pressure can be appropriately increased to improve the convergence performance of the melt. A small amount of lubricant can also be added to the raw material formula to improve the flow performance of the melt.

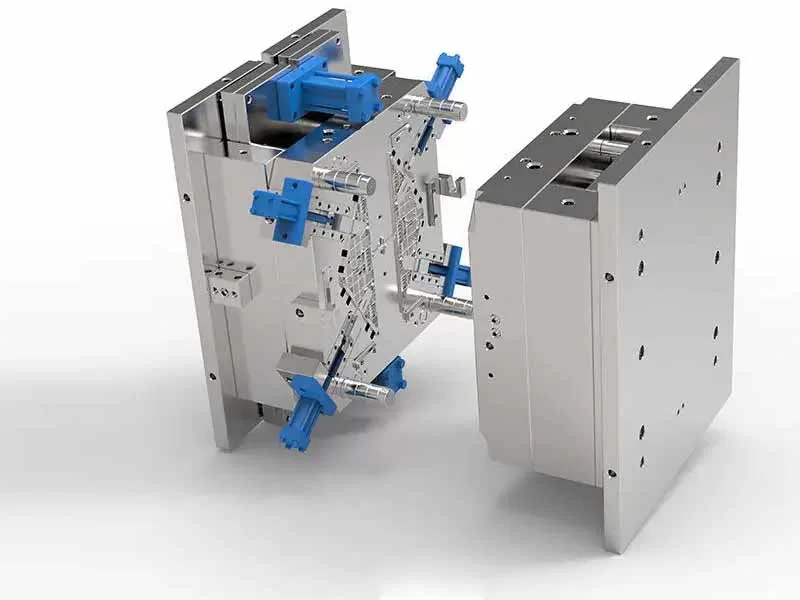

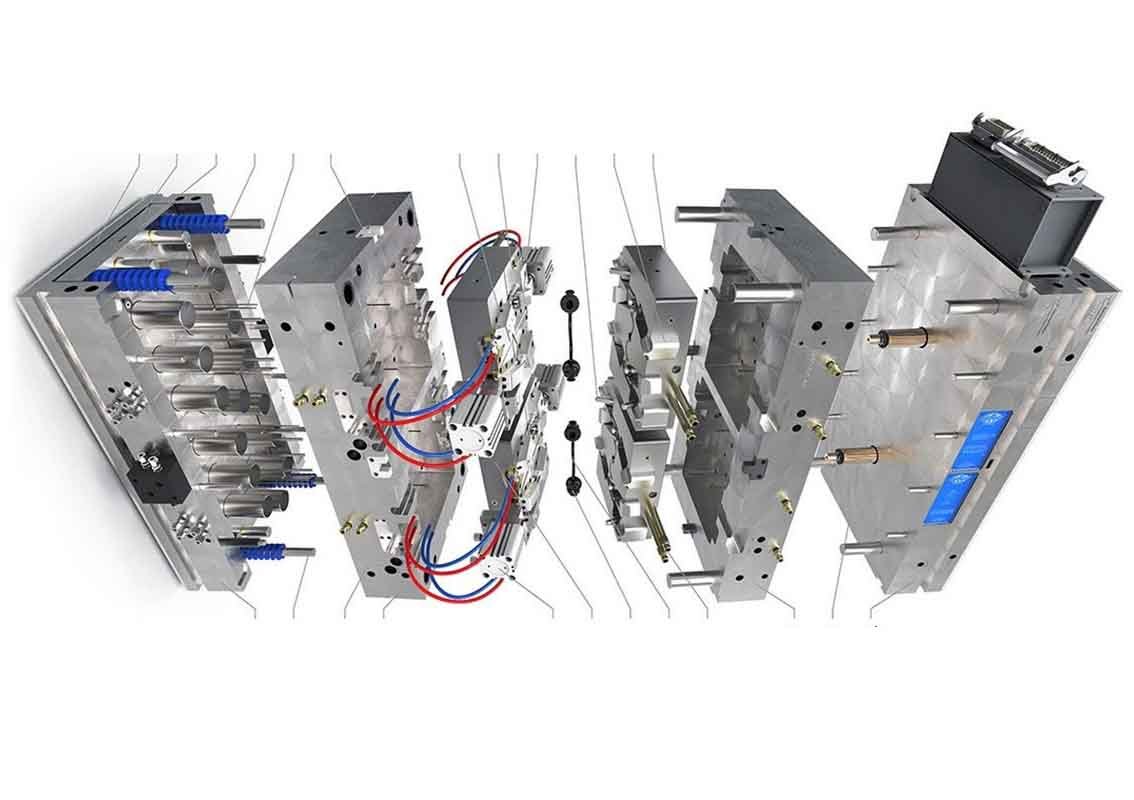

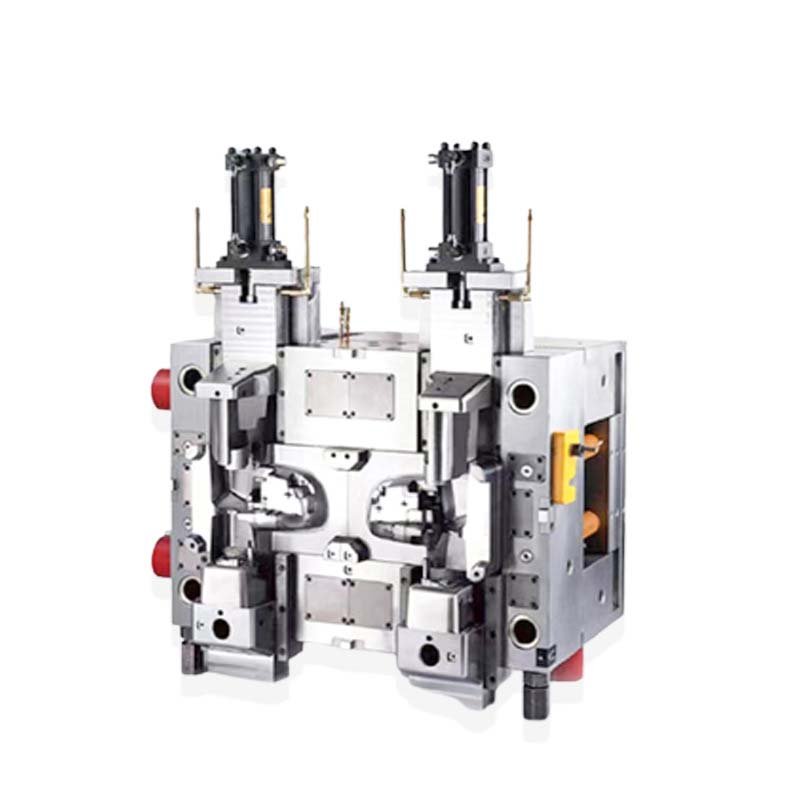

2. Mold defects

The structural parameters of the mold casting system have a great influence on the welding condition of the flow material, because poor welding is mainly caused by the diversion and convergence of the melt. Therefore, the gate form with less diversion should be used as much as possible and the gate position should be reasonably selected to avoid inconsistent filling rate and interruption of filling material flow. Under possible conditions, a one-point gate should be used, because this gate does not produce multiple streams, the melt will not converge from two directions, and it is easy to avoid welding marks.

If there are too many or too small gates in the casting system of the mold, the multi-gate positioning is incorrect or the distance from the gate to the flow material welding point is too large, the main flow channel inlet of the casting system and the flow channel section of the diversion channel are too small, resulting in too large material flow resistance, which will cause poor welding and produce more obvious welding marks on the surface of the plastic part. In this regard, the number of gates should be reduced as much as possible, the gate position should be set reasonably, the gate section should be increased, the auxiliary flow channel should be set, and the main flow channel and diversion channel diameter should be expanded.

In order to prevent low-temperature molten material from being injected into the mold cavity and causing weld marks, a cold material hole should be set in the mold while increasing the mold temperature.

In addition, the location where the weld marks of plastic parts are produced often produces flash due to high-pressure mold filling, and the weld marks will not produce shrinkage holes after such flashes are produced. Therefore, such flashes are often not used as troubleshooting, but a very shallow groove is opened at the location where the flash is produced on the mold to transfer the weld marks on the plastic parts to the additional flash winglets, and then the winglets are removed after the plastic parts are formed. This is also a common method for troubleshooting weld mark faults.

3. Poor mold exhaust

When the weld line of the molten material coincides with the mold joint line or caulking of the mold, the air squeezed by multiple streams of flow materials in the mold cavity can be discharged from the mold joint gap or caulking;

But when the weld line does not coincide with the mold joint line or caulking, and the exhaust hole is not set properly, the residual air squeezed by the flow materials in the mold cavity cannot be discharged, and the bubbles are strongly squeezed under high pressure, and the body gradually becomes smaller and finally compressed into a point. Since the molecular kinetic energy of the compressed air is converted into heat energy under high pressure, the temperature at the melt confluence point increases. When its temperature is equal to or slightly higher than the decomposition temperature of the raw material, yellow spots appear at the weld point. If its temperature is much higher than the decomposition temperature of the raw material, black spots appear at the weld point.

Generally speaking, such spots appearing near the weld mark on the surface of the plastic part always appear repeatedly at the same position, and the parts that appear always appear regularly at the confluence point. During operation, such spots should not be mistaken for impurity spots. The main reason for such spots is poor mold exhaust, which is a carbonization point formed after the high-temperature decomposition of the molten material.

After this type of failure occurs, first check whether the mold vent is blocked by solidified materials or other objects of the melt, and whether there are foreign objects at the gate. If carbonization points still appear after the blockage is removed, add vents at the mold confluence point. You can also accelerate the confluence of materials by repositioning the gate or appropriately reducing the mechanical force and increasing the venting gap. In terms of process operation, auxiliary measures such as lowering the material temperature and mold temperature, shortening the high-pressure injection time, and reducing the injection pressure can also be taken.

4. Improper use of release agent

Excessive use of release agent or incorrect selection of varieties will cause welding marks on the surface of plastic parts. In injection molding, a small amount of release agent is generally applied evenly only on parts such as threads that are difficult to demold. In principle, the amount of release agent should be minimized.

The selection of various release agents must be determined based on molding conditions, plastic part shape, and raw material varieties. For example, pure zinc stearate can be used for various plastics except polyamide and transparent plastics, but it can be used for polyamide and transparent plastics after mixing with oil. For example, silicone oil toluene solution can be used for various plastics, and it can be used for a long time after being applied once, but it needs to be heated and dried after application, and its use is relatively complicated.

5. Unreasonable plastic structure design

If the wall thickness of the plastic part is designed to be too thin, the thickness difference is too large, and there are too many inserts, it will cause poor welding. When thin-walled parts are molded, defects are easy to occur because the molten material solidifies too quickly, and the molten material always converges at the thin wall during the mold filling process to form a weld mark. Once a weld mark is generated at the thin wall, the strength of the plastic part will be reduced, affecting the performance.

Therefore, when designing the shape structure of the plastic part, it should be ensured that the thinnest part of the plastic part must be greater than the minimum wall thickness allowed during molding. In addition, the use of inserts should be minimized and the wall thickness should be as consistent as possible.

6. Other reasons

When the moisture or volatile content of the raw materials used is too high, the oil stains in the mold are not cleaned, there is cold material in the mold cavity or the fiber filler in the melt is poorly distributed, the mold cooling system is not designed reasonably, the melt solidifies too quickly, the insert temperature is too low, the nozzle hole is too small, the plasticizing capacity of the injection molding machine is insufficient, and the pressure loss in the injection molding machine barrel is too large, it will lead to different degrees of poor welding.

In this regard, during the operation process, according to different situations, measures such as pre-drying of raw materials, regular cleaning of molds, changing the setting of mold cooling water channels, controlling the flow of cooling water, increasing the insert temperature, replacing nozzles with larger apertures, and using larger injection molding machines should be taken to solve the problem.