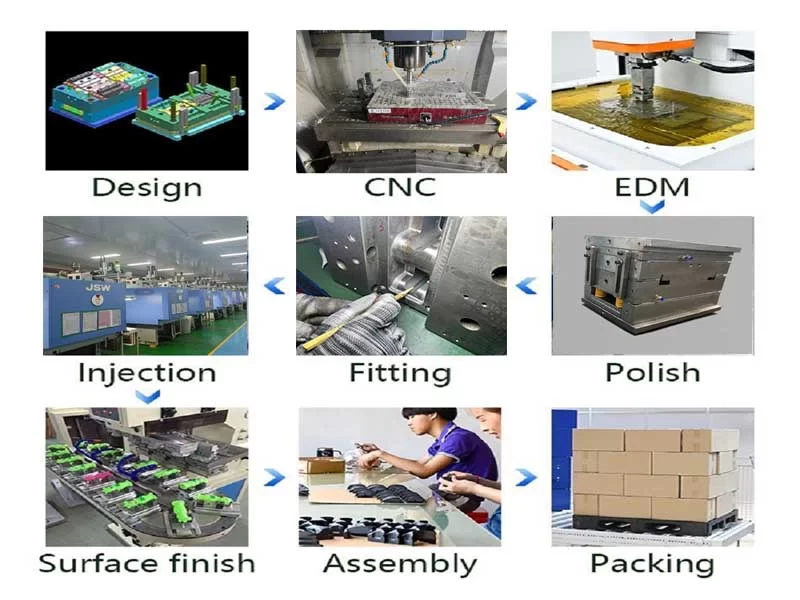

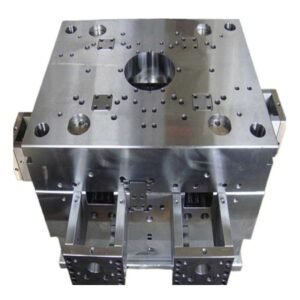

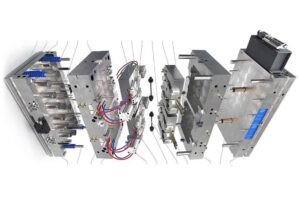

Your Reliable plastic injection molding Manufacturer

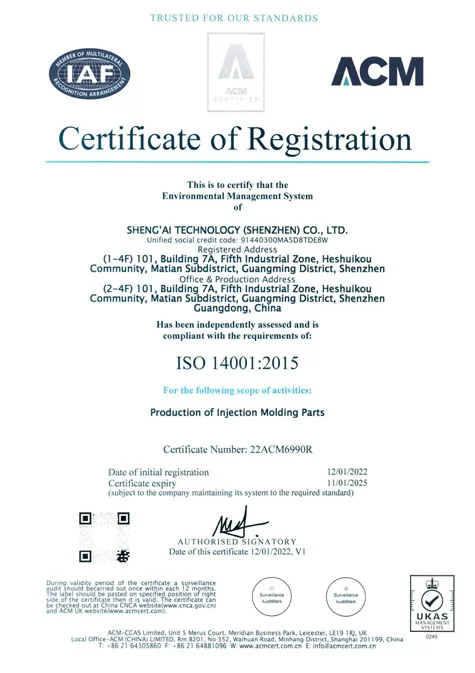

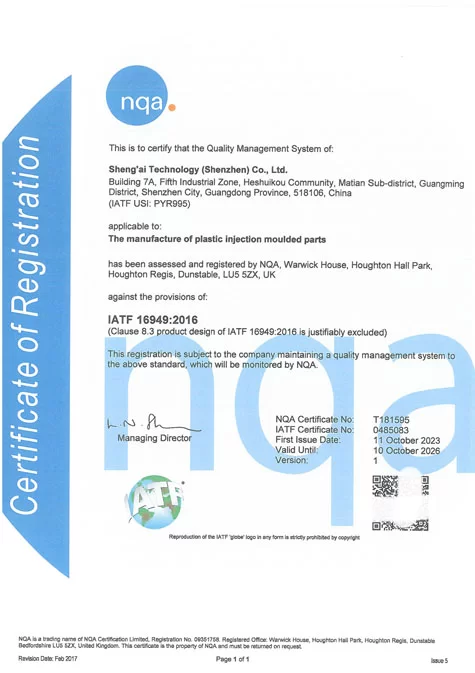

A premier B2B manufacturer specializing in plastic injection molding. With over a decade of experience in the industry, we pride ourselves on delivering cutting-edge solutions tailored to our clients’ needs. Our dedicated team of experts combines extensive knowledge with a commitment to excellence, ensuring the highest standards in every product we produce. From prototyping to full-scale production, we leverage advanced technologies to offer superior quality and precision in every component.

With a decade-long track record of delivering exceptional results, we lead the industry with our advanced technologies and specialized team. Our commitment to quality is unmatched, as we meticulously oversee every stage of production to ensure precision and reliability.

Send Inquiry