PC raw materials have excellent performance, high transparency, good impact toughness, creep resistance, and a wide range of operating temperatures. The process characteristics of PC are: the melt viscosity is less sensitive to shear rate, but more sensitive to temperature, there is no obvious melting point, the melt viscosity is high, the resin is easy to hydrolyze at high temperature, and the product is easy to crack. In view of these characteristics, we must pay special attention to different treatments: to increase the fluidity of the melt, it should not be achieved by increasing the injection pressure but by increasing the injection temperature. The runners and gates of the mold are required to be short and thick to reduce the pressure loss of the fluid, and at the same time, a higher injection pressure is required. The resin needs to be fully dried before molding to control its water content below 0.02%. In addition, during the processing of AR Glasses Injection Molding Products, insulation measures should be taken for the resin to prevent re-absorption of moisture. Not only reasonable product design is required, but also the molding process should be correctly mastered, such as increasing the mold temperature and post-processing the product to reduce or eliminate internal stress. Adjust the process parameters in time according to the different conditions of the product. Let’s talk about the molding process.

1. The injection temperature must be considered in combination with the shape, size, and mold structure of the product. The product performance, requirements, and other aspects can be made after consideration. Generally, the temperature used in molding is between 270 and 320°C. If the material temperature is too high, such as exceeding 340°C, PC will decompose, the color of the product will become darker, and defects such as silver wire, dark stripes, black spots, and bubbles will appear on the surface. At the same time, the physical and mechanical properties will also decrease significantly.

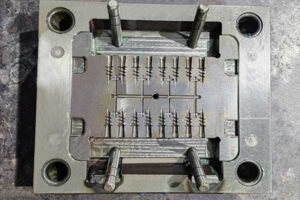

2. Injection pressure has a certain influence on the physical and mechanical properties, internal stress, and molding shrinkage of PC products. It has a greater impact on the appearance and demolding of the product. Too low or too high injection pressure will cause certain defects in the product. Generally, the injection pressure is controlled between 80-120MPa. For thin-walled, long-flow, complex-shaped, and small-gate products, in order to overcome the resistance of melt flow and fill the mold cavity in time, a higher injection pressure (120-145MPa) is selected. In this way, a complete and smooth-surfaced product is obtained.

3. Holding pressure and holding time The size of the holding pressure and the length of the holding time have a great influence on the internal stress of PC products. If the holding pressure is too small, the shrinkage compensation effect is small, and vacuum bubbles or shrinkage concavities on the surface are likely to occur. If the holding pressure is too large, it is easy to generate large internal stress around the gate. In actual processing, it is often solved by high material temperature and low holding pressure. The choice of holding time should be determined by the thickness of the product, the size of the gate, the mold temperature, etc. Generally, small and thin products do not need a long holding time. On the contrary, large and thick products should have a longer holding time. The length of the holding time can be determined by the gate sealing time test.

4. Injection speed It has no obvious effect on the performance of PC products. Except for thin-walled, small gates, deep holes, and long-process products, medium or slow processing is generally adopted. Multi-stage injection is best, and slow-fast-slow multi-stage injection is generally adopted.

5. Mold temperature Generally, it can be controlled at 80-100℃. For products with complex shapes, thinner shapes and higher requirements, it can also be increased to 100-120℃, but it cannot exceed the mold thermal deformation temperature.

6. Screw speed and back pressure Since PC melt viscosity is relatively high, it is beneficial to plasticization, exhaust, maintenance of the molding machine, and prevent excessive screw load. The screw speed requirement should not be too high. It is generally controlled at 30-60r/min, and the back pressure should be controlled between 10-15% of the injection pressure.

7. The use of release agent should be strictly controlled during the PC injection molding process. At the same time, the use of recycled materials should not exceed three times, and the amount used should be about 20%. Requirements for plastic machines for producing PC products: The maximum injection volume of the product (including runners, gates, etc.) should not be greater than 70-80% of the nominal injection volume. The screw should use a single-start thread with equal pitch and a gradual compression screw with a check ring. The screw’s length-to-diameter ratio L/D is 15-20, and the geometric compression ratio C/R is 2-3.