Custom Injection Molding Services is a widely utilized manufacturing process that allows for the production of high-quality, intricate plastic components. When it comes to selecting an injection molding service provider, it is crucial to choose a company that not only meets your requirements but also exceeds expectations. we will explore the advantages and unique features […]

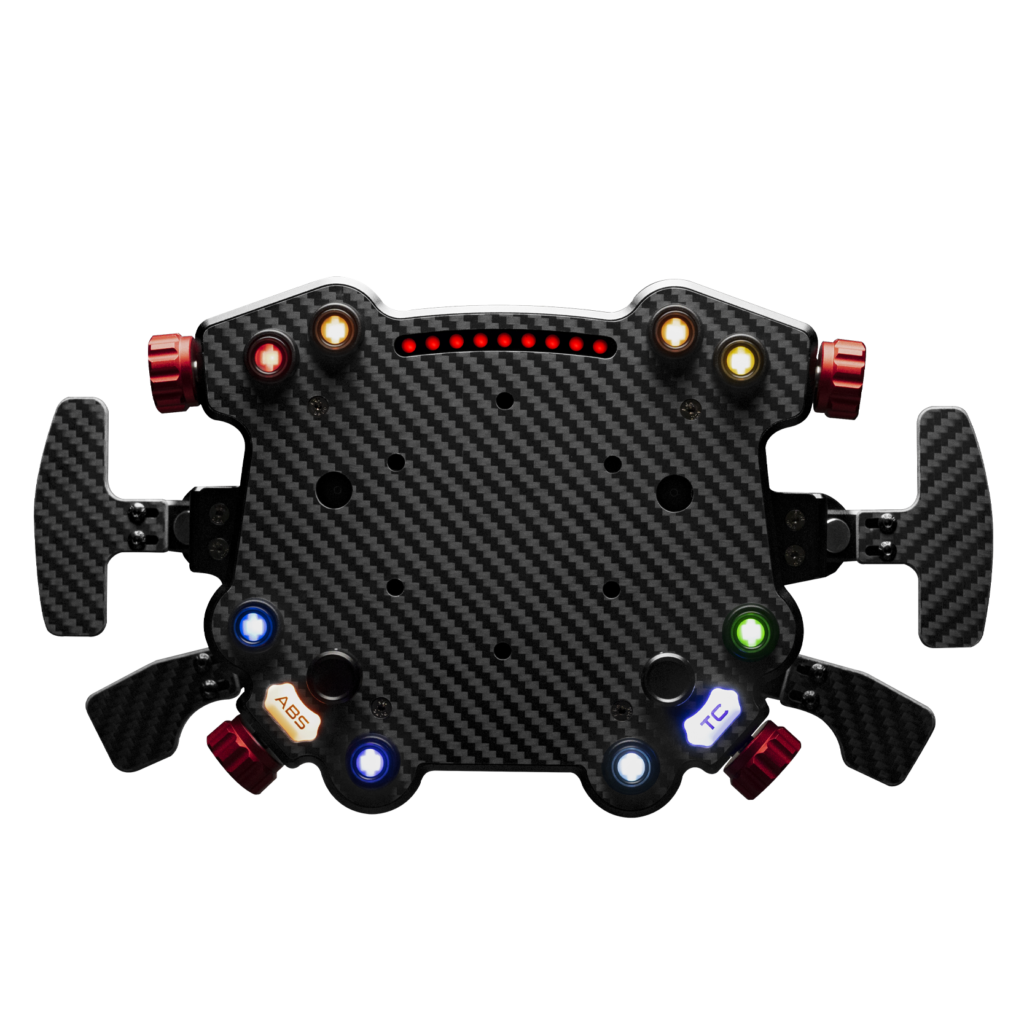

Injection molding is a widely used manufacturing process for producing plastic parts and products. Finding the right Game controller injection molding manufacturer is crucial for businesses to ensure high-quality and efficient production. We will present a comprehensive table showcasing the specific parameters of an injection molding manufacturer, emphasizing their advantages and unique features. The Importance […]

Unveiling the Expertise of High Volume, Small Plastic Parts Injection Molding abs plastic molding manufacturers In the realm of manufacturing, precision and efficiency are paramount. When it comes to the production of high volume, small plastic parts, the need for a reliable and specialized partner becomes even more critical. Case Study: Transforming an Industry with […]

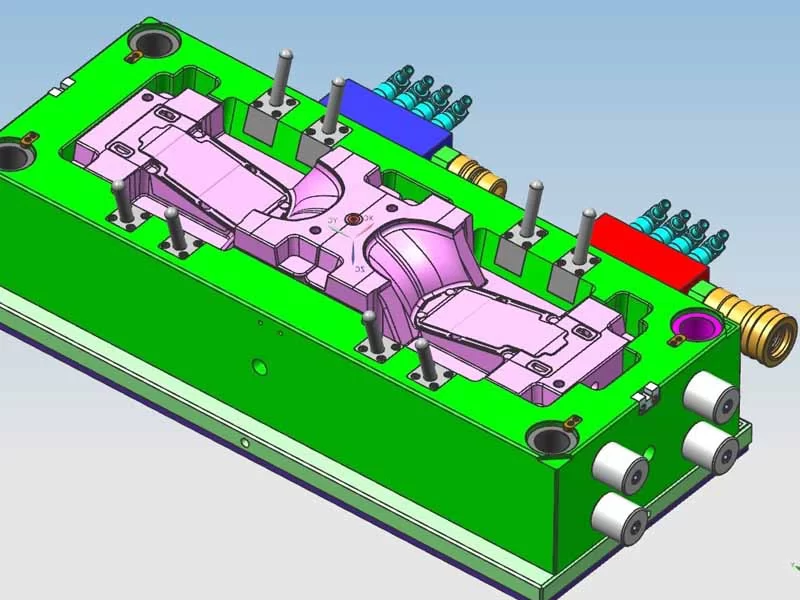

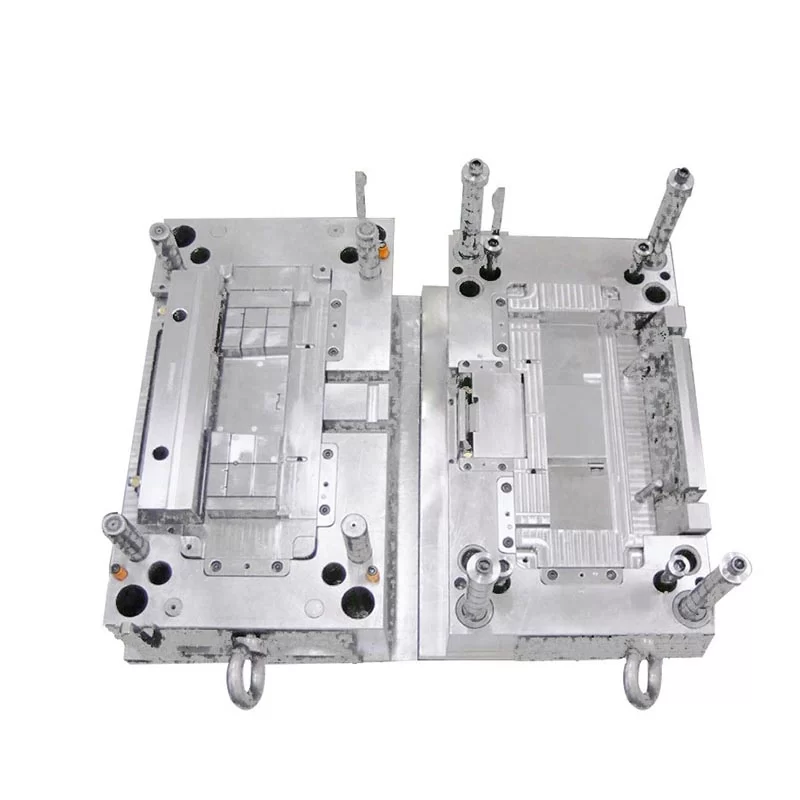

During the injection molding process, product dimension control is a crucial link. In order to ensure the dimensional accuracy and quality stability of the product, it is necessary to carry out comprehensive control from multiple aspects such as mold design, process manufacturing and production management. The following are some specific experiences and suggestions for the […]

Co-injection is a sequential type of multi-component technology where the second component (core) is injected into the first component (skin). A specialized co-injection nozzle utilizes a pressure differential to control the ratio between the two components. This technique can reduce costs by allowing the use of less expensive core materials, such as regrind. Additionally, it […]

Liquid silicone rubber injection molding manufacturer (LSR) is a high-performance two-part thermosetting elastomer with unique organic and inorganic properties (watch this video). This silicone elastomer has a typical viscosity range of 500,000 to 2,000,000 centipoise (cps). Due to its wide process applicability, high temperature stability, low temperature flexibility, excellent weather resistance, long service life, good […]

Plastic Contract Manufacturing Companies Plastic Injection Molding Defects: Causes and Solutions Filling Defects Filling defects often result in incomplete filling or edge collapse, leading to defective products, wasted material, labor, and time. Possible causes include:Nozzle Temperature: Too low Material Supply: Insufficient Flowability: Poor Injection Pressure: Too low Gate: Too small or incorrectly positioned Mold Surface: […]

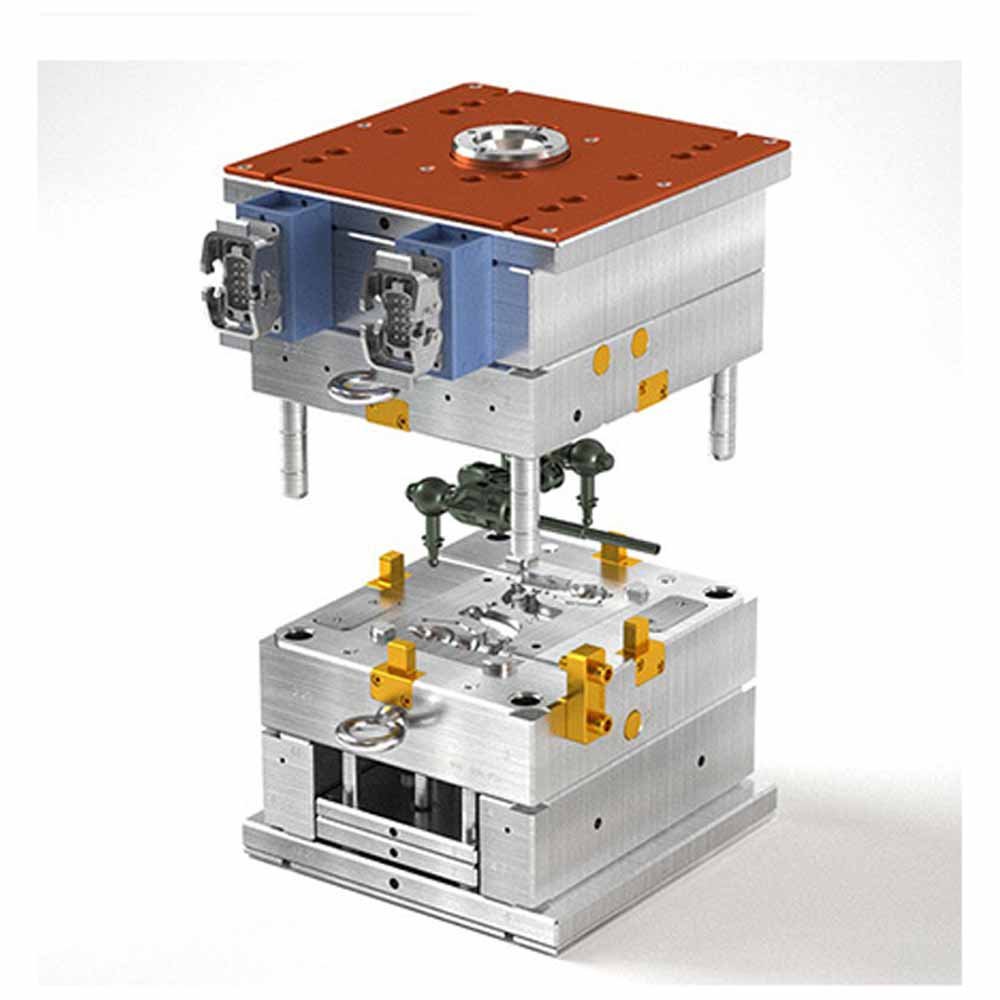

Understanding the Estimation of Injection Mold Prices Estimating the cost of an injection mold involves several key steps to ensure accuracy and transparency for both plastic injection molding Manufacturer and the customer. Here’s a breakdown of the process: Material Selection and Manufacturing Process: The first step is to select the appropriate steel and manufacturing process […]

Factor 1: When plastic is injected into a large cavity under high pressure, melt fracture is very likely to occur. At this time, transverse fractures appear on the surface of the melt, and the fracture area is roughly mixed in the surface of the plastic part to form a burnt spot. Especially when a small […]

Introduction The temperature inside the mold during center console injection molding is the most important variable in injection molding – no matter what kind of plastic, it must ensure that the mold surface is basically wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure in the cavity. If the […]