Custom Injection Molding Services is a widely utilized manufacturing process that allows for the production of high-quality, intricate plastic components. When it comes to selecting an injection molding service provider, it is crucial to choose a company that not only meets your requirements but also exceeds expectations. we will explore the advantages and unique features of our company’s injection molding services, supported by a case study and a detailed table of specific parameters.

The Importance of Choosing the Right Injection Molding Service Provider

1.1. Precision and Quality

Injection molding is a complex process that demands precision and accuracy. The right service provider ensures that every component produced meets the highest quality standards. By selecting our company’s injection molding services, you gain access to state-of-the-art technology and expertise that guarantees exceptional results.

1.2. Customization and Flexibility

Every project is unique, and our injection molding services are designed to cater to your specific needs. Whether you require small-scale production or large-volume manufacturing, our company offers the flexibility to adapt to your requirements. Let’s explore a case study that highlights our capabilities.

Case Study: Custom Molded Components for Automotive Industry

A leading automotive manufacturer approached our company for custom molded components. They needed high-quality, precision-engineered parts that could withstand the rigorous demands of the automotive industry. Our team worked closely with the client to understand their requirements and delivered customized components that met their exact specifications. The end result was a successful partnership that resulted in improved vehicle performance and customer satisfaction.

Advantages and Unique Features of Our Injection Molding Services

2.1. Advanced Technology and Equipment

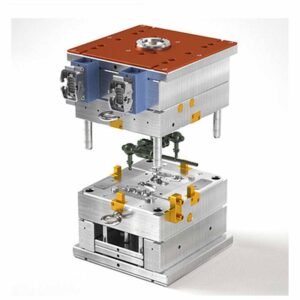

Our company prides itself on utilizing cutting-edge technology and state-of-the-art equipment. This enables us to deliver precise and efficient injection molding services. Here are some of the advantages and unique features that set us apart:

- High-speed injection molding machines for rapid production cycles

- Robotic automation for increased accuracy and reduced human error

- Advanced cooling systems for improved part quality and cycle time reduction

- Real-time monitoring and process control for consistent results

2.2. Material Expertise

We understand that selecting the right material is crucial for the success of your project. Our team has extensive knowledge of various plastic materials and can recommend the most suitable option based on your specific requirements. Here are some of the materials we work with:

- ABS (Acrylonitrile Butadiene Styrene)

- PC (Polycarbonate)

- Nylon

- PP (Polypropylene)

- TPU (Thermoplastic Polyurethane)

- POM (Polyoxymethylene)

2.3. Quality Assurance

Maintaining the highest quality standards is our top priority. Our injection molding services include rigorous quality control measures to ensure that every component meets your expectations. Here’s a glimpse of our quality assurance process:

- Dimensional inspections using precision measuring instruments

- Visual inspections to detect any surface defects or imperfections

- Material testing to ensure compliance with industry standards

- Continuous improvement initiatives to enhance product quality

Injection Molding Service Services: Detailed Parameters

Below is a table showcasing the specific parameters of our injection molding services:

| Parameter | Description |

|---|---|

| Machine Size | Various sizes available to accommodate different project requirements |

| Clamp Force | Ranging from 50 to 500 tons to handle diverse part sizes |

| Shot Size | Customizable shot sizes to accommodate various part volumes |

| Injection Speed | High-speed injection for fast cycle times |

| Pressure | Maximum injection pressure to ensure precise mold filling |

| Material Temperature | Accurate temperature control for optimal material flow and part quality |

| Cooling System | Advanced cooling systems for reduced cycle times and improved part quality |

| Automation | Robotic automation for increased efficiency and reduced human error |

| Quality Control | Rigorous quality assurance measures for consistent results |

| Lead Time | Competitive lead times without compromising on quality |

| Post-Processing Services | Optional services such as painting, assembly, and packaging |

When it comes to injection molding services, selecting the right partner is crucial for achieving exceptional results. Our company offers a comprehensive range of services, advanced technology, material expertise, and rigorous quality assurance measures. By choosing our Custom Injection Molding Services, you can expect precision, customization, and superior quality. Contact us today to discuss your specific requirements and experience the difference that sets us apart.