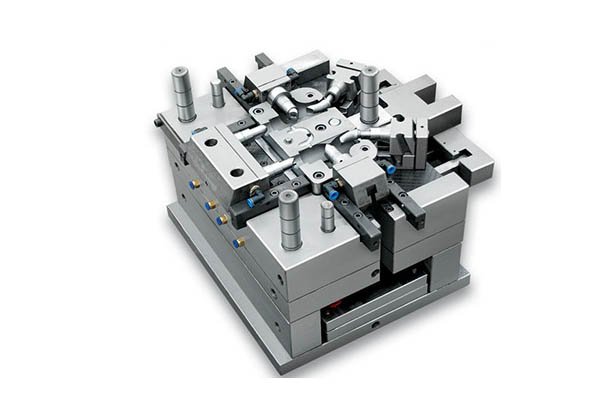

During the injection molding process of electronic product shells, brittle cracking is a common problem that may be caused by a variety of factors. The following are analysis and improvement suggestions for molds, equipment, raw materials, processes and product design. 1. Mold aspect 1. Gate size: If the gate is too small, consider adjusting the […]

Tag Archives: Electronic product shell processing factory

Flash, also known as overflow, burr or burr, usually occurs at the parting position of the mold, such as the parting surface of the dynamic mold and the static mold, the sliding part of the slider, the absolute gap of the insert and the pore of the ejector pin. The generation of flash is largely […]

1. Pigment and dye additives Another way to identify whether plastic parts are genuine is to mix plastic parts with pigments or dyes. Electronic product shell processing factories use spectrometers to analyze the exposed parts and ultraviolet areas. Those pigments or dyes will show unique patterns. Even if counterfeiters use extremely similar colors on their […]

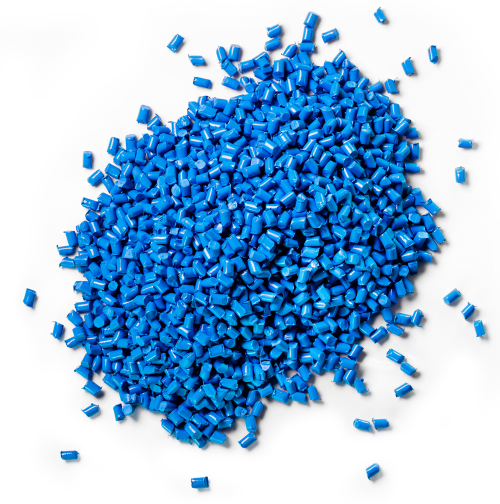

Electronic product shell processing factory after the formula of the filling masterbatch is determined, the granulation process is an important factor that determines the quality of the masterbatch. (1) Heating temperature The heating temperature depends on the softening point or melting temperature of the carrier resin. The higher the softening point or melting temperature of […]

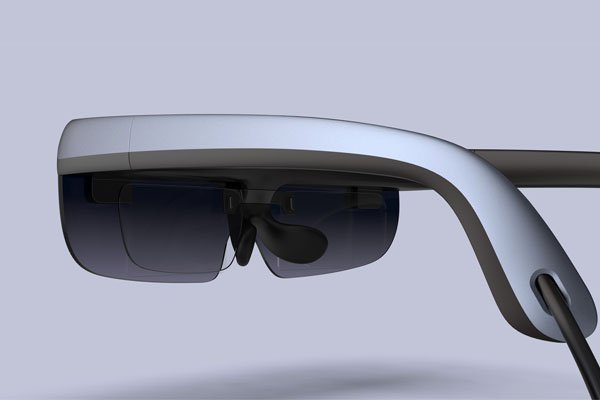

1. AR Glasses Injection Molding Products formation of white lines 1.1 Microscopic explanation of white lines: When plastic is subjected to tensile stress, cavitation stripe-shaped deformation areas are generated due to stress concentration. These stripe plane areas strongly reflect visible light, forming a silver-white luster on the surface of the material, commonly known as white lines. […]

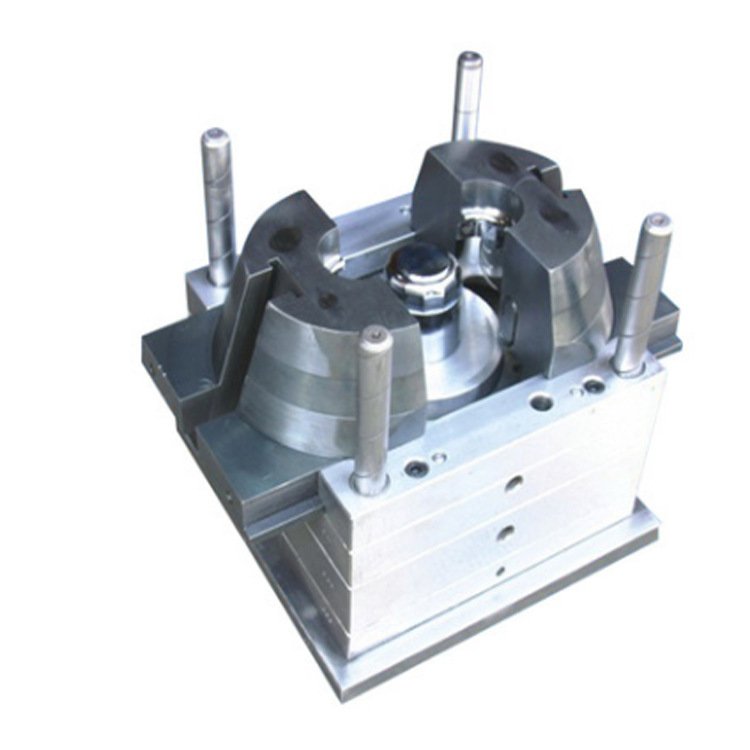

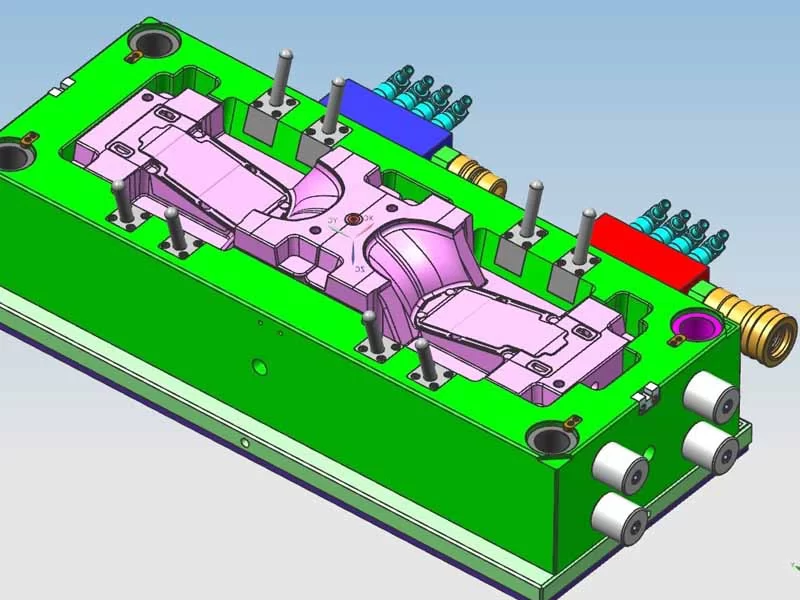

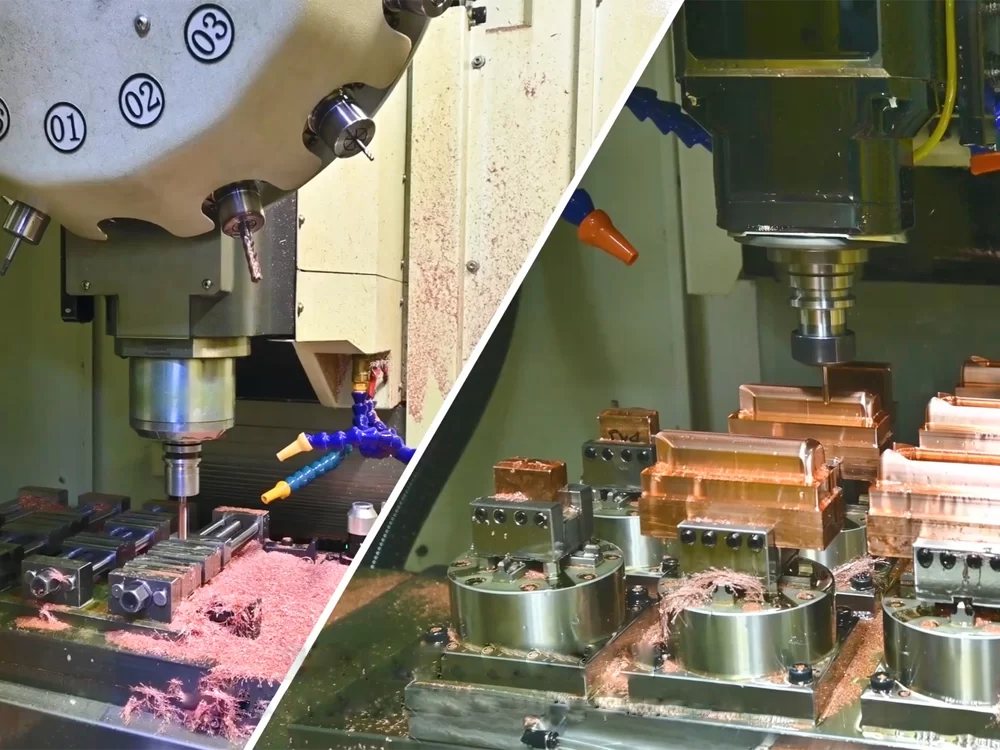

Injection molds should be tested for various properties of the mold under normal operation of the injection molding machine and mold, and the dimensions of the final molded plastic parts should be measured. This information can be used to determine the current state of the mold, find out where the cavity, core, cooling system and […]

Plastic Contract Manufacturing Companies Plastic Injection Molding Defects: Causes and Solutions Filling Defects Filling defects often result in incomplete filling or edge collapse, leading to defective products, wasted material, labor, and time. Possible causes include:Nozzle Temperature: Too low Material Supply: Insufficient Flowability: Poor Injection Pressure: Too low Gate: Too small or incorrectly positioned Mold Surface: […]

Factor 1: When plastic is injected into a large cavity under high pressure, melt fracture is very likely to occur. At this time, transverse fractures appear on the surface of the melt, and the fracture area is roughly mixed in the surface of the plastic part to form a burnt spot. Especially when a small […]

Introduction With the continuous improvement of Automobile injection molding technology, it is imperative to minimize the shrinkage problem of plastic injection molding and improve product quality. Solution The shrinkage formed in the thicker parts of plastic injection molding parts, such as ribs or protrusions, is more serious than that in adjacent positions. This is because […]