During the injection molding process of center console, gas lines often appear at the water inlet of PC plastic products, mainly because the injection speed is too fast. To solve this problem, we need to reduce the injection speed and avoid the occurrence of vibration lines and material shortage. 1. Increase the melt temperature First, […]

Tag Archives: center console injection molding

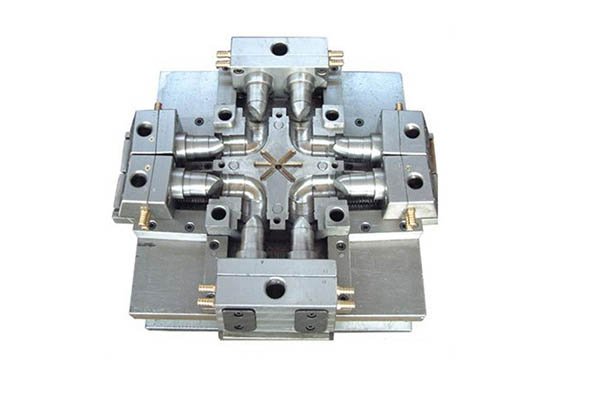

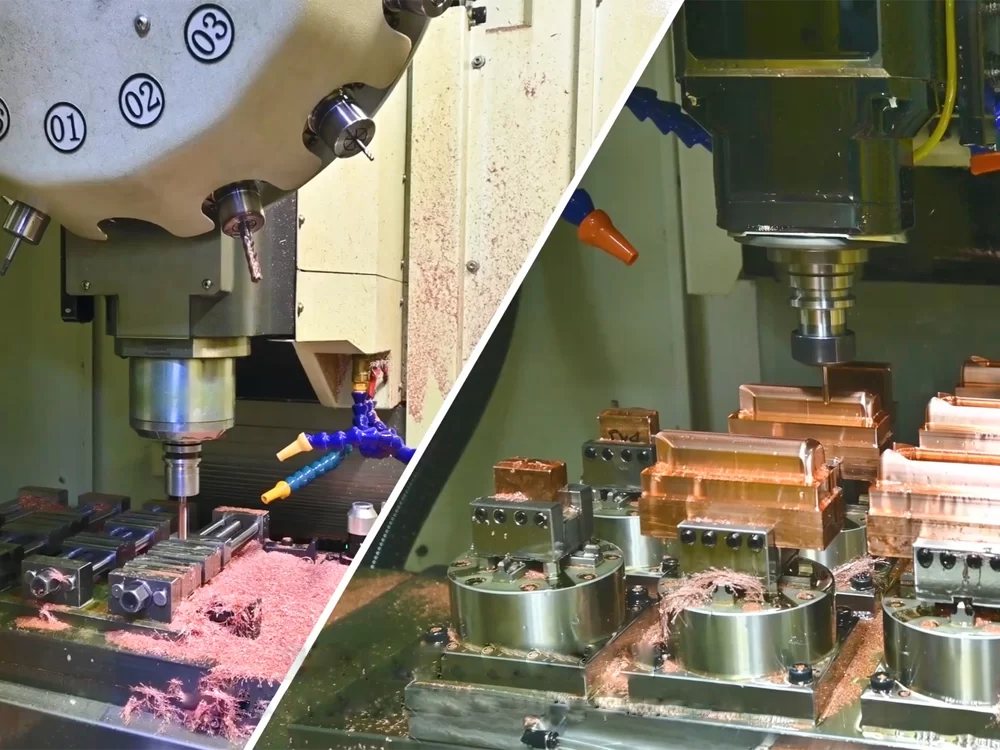

Automotive plastic parts, such as coil skeletons, bases, fuse boxes, lamp holders, blade fuses, central distribution boxes, sheaths, push racks, center console injection molding and outer covers, are mostly injection molded. Since these plastic parts have high design accuracy, conventional injection molding cannot be used for these plastic parts, but precision injection molding technology must […]

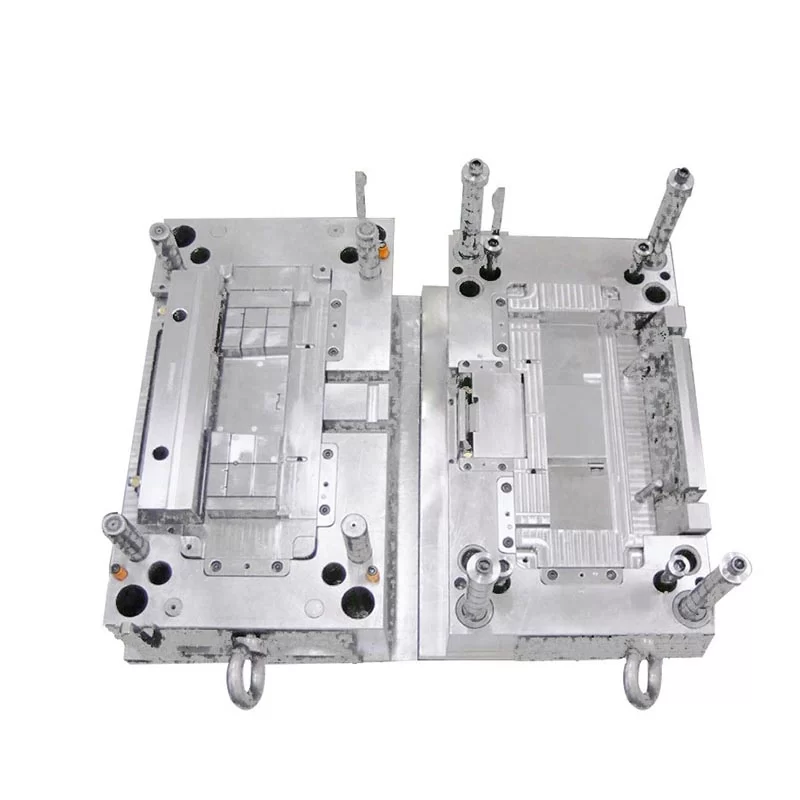

Analysis of causes and countermeasures of black spots and impurities in center console injection molding. Defects of black spots and impurities are the most important factors that cause scrap rates in normal production processes. They mainly affect the appearance of products and lead to scrapping. Impurities and most black spots are foreign substances and have […]

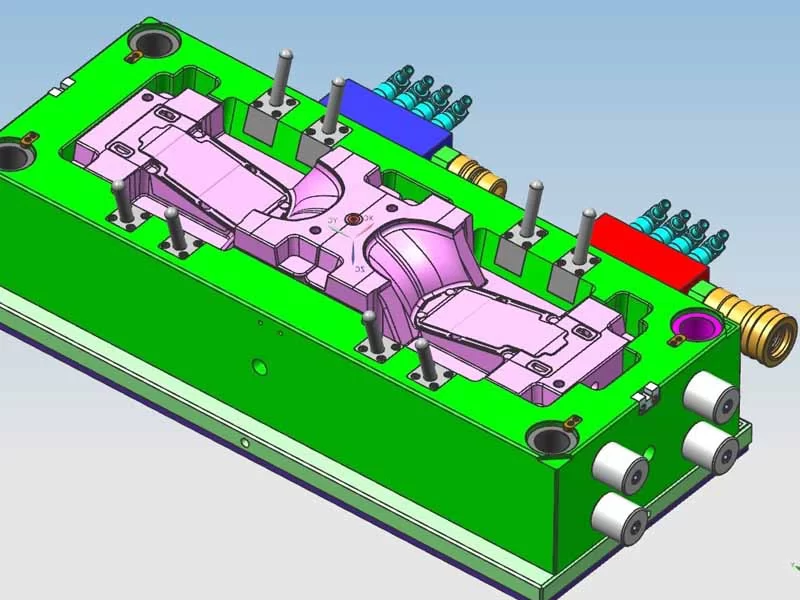

Most of the parts on the interior and exterior of the center console injection molding. The interior plastic parts generally include instrument panel accessories, seat accessories, floor accessories, roof accessories, steering wheel accessories, door interior accessories, rearview mirrors and various buckles and fixings; the exterior plastic parts include front and rear lights, air intake grilles, […]

Factor 1: When plastic is injected into a large cavity under high pressure, melt fracture is very likely to occur. At this time, transverse fractures appear on the surface of the melt, and the fracture area is roughly mixed in the surface of the plastic part to form a burnt spot. Especially when a small […]

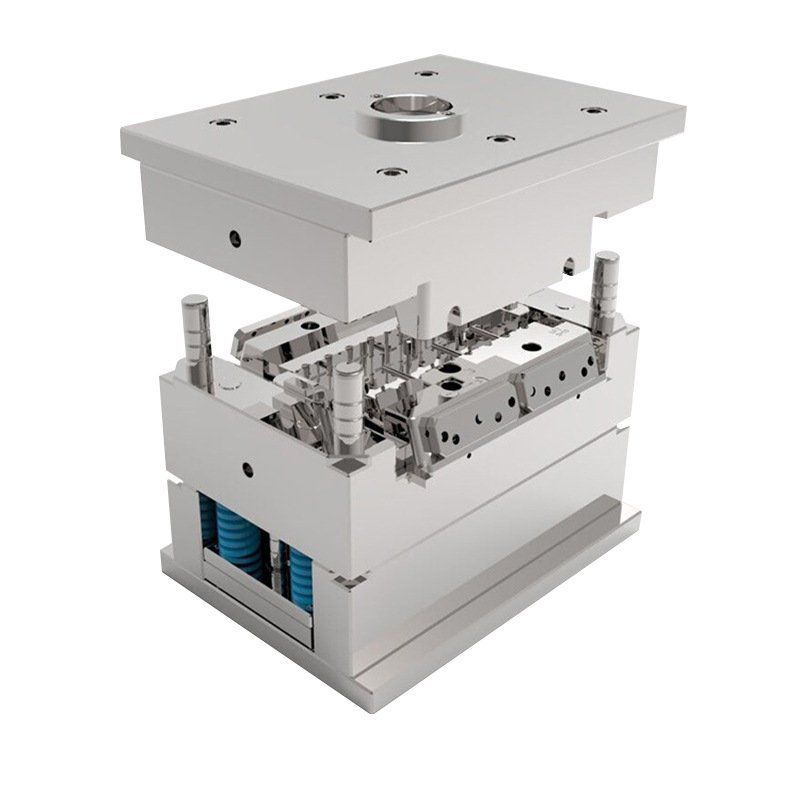

Introduction The temperature inside the mold during center console injection molding is the most important variable in injection molding – no matter what kind of plastic, it must ensure that the mold surface is basically wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure in the cavity. If the […]

Introduction With the continuous improvement of Automobile injection molding technology, it is imperative to minimize the shrinkage problem of plastic injection molding and improve product quality. Solution The shrinkage formed in the thicker parts of plastic injection molding parts, such as ribs or protrusions, is more serious than that in adjacent positions. This is because […]