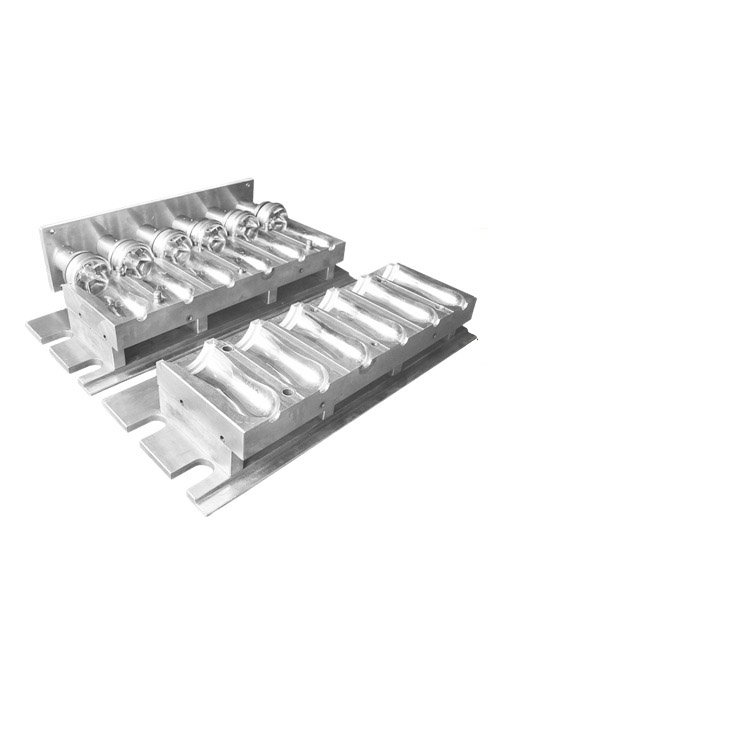

Charger shell manufacturers focus on the production of plastic products and have an in-depth understanding of the processing technology of injection molded parts. Before producing chargers, they will first study the shape and production process of the product and design a suitable mold. Only when the chargers made by the mold are qualified in all […]

Tag Archives: custom plastic injection molding

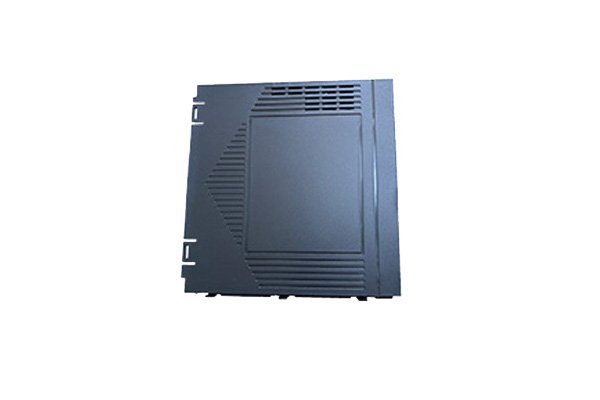

Router Injection Molding Products poor demolding, also known as die adhesion, occurs when sprues or molded parts stick to the mold, often due to inadequate contact between the injection port and the nozzle arc, incomplete removal of gate material, or abnormal filler conditions. The main runner diameter must be sufficiently large to ensure that the […]

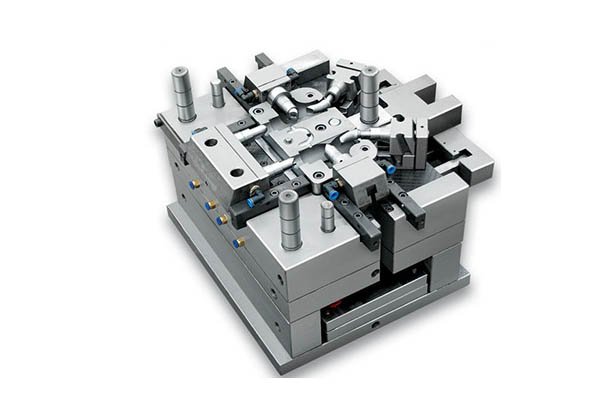

The influence of custom plastic injection molding gate on parts and the selection of position 1. Requirements for gate position: 1. Appearance requirements (gate marks, weld lines) 2. Product function requirements 3. Mold processing requirements 4. Product warping 5. Is the gate easy to remove 2. Impact on production and function: 1. Flow length determines […]

As a cheap and high-performance engineering plastic, PPS is increasingly widely used in custom plastic injection molding. However, its molding characteristics have always been a constraint on its widespread use, and how to improve its burrs is also a problem explored by various molding departments. 1. Introduction to the characteristics of PPS engineering materials PPS, […]

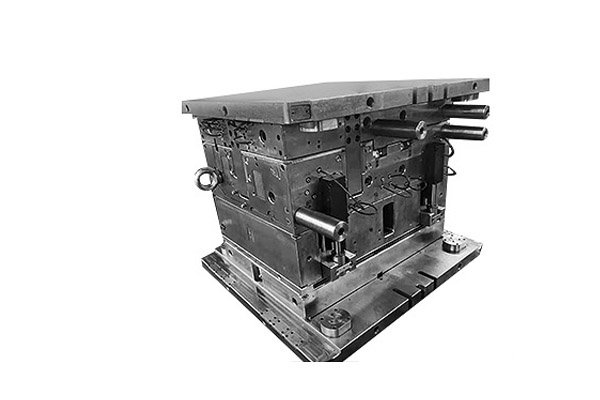

Injection molds should be tested for various properties of the mold under normal operation of the injection molding machine and mold, and the dimensions of the final molded plastic parts should be measured. This information can be used to determine the current state of the mold, find out where the cavity, core, cooling system and […]

During the injection molding process, product dimension control is a crucial link. In order to ensure the dimensional accuracy and quality stability of the product, it is necessary to carry out comprehensive control from multiple aspects such as mold design, process manufacturing and production management. The following are some specific experiences and suggestions for the […]