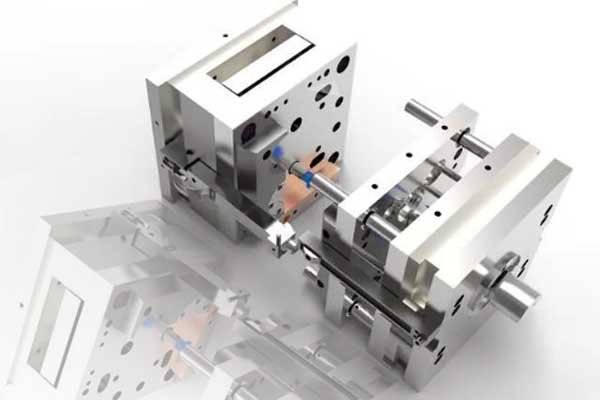

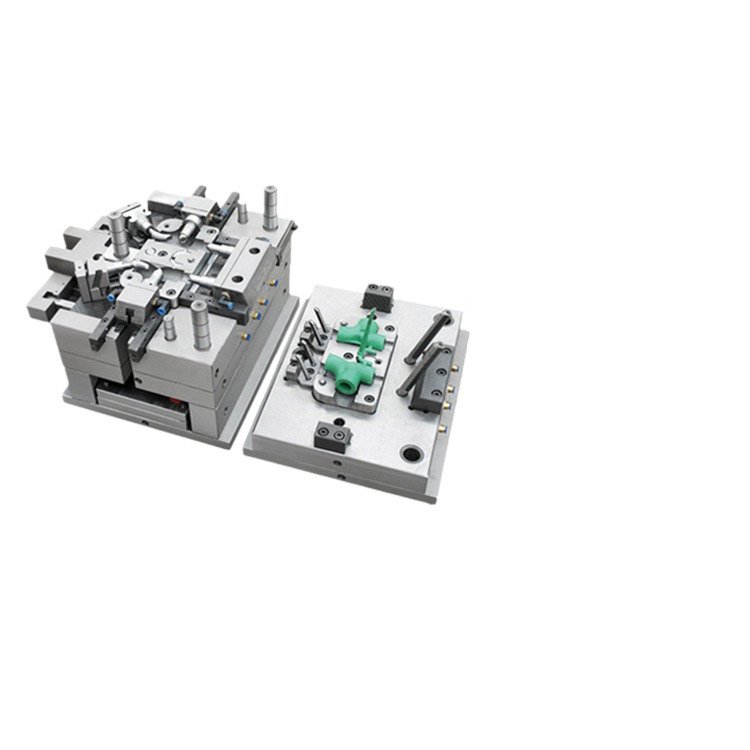

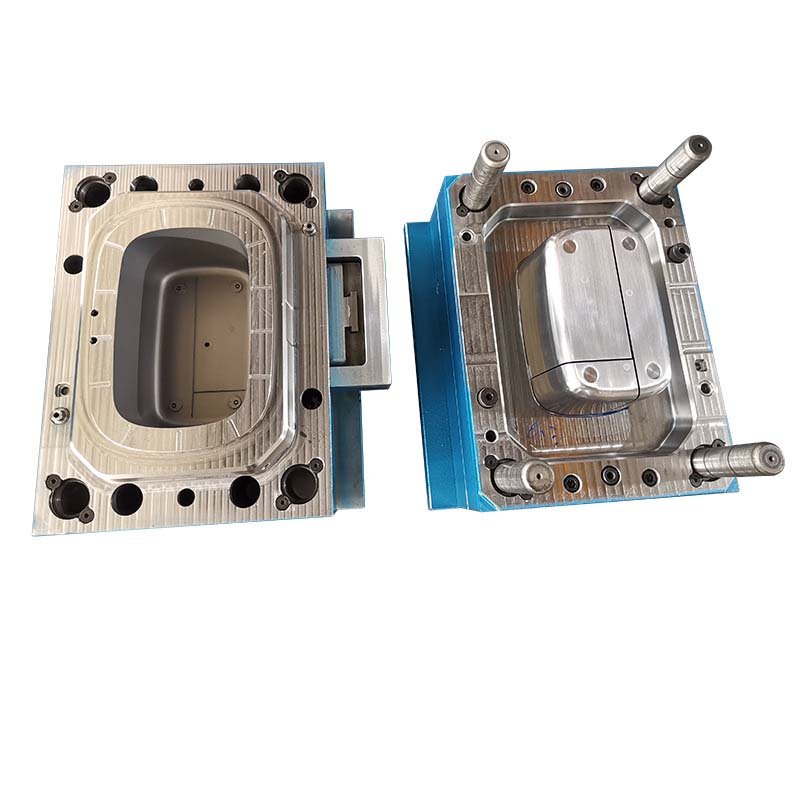

Precision mold design and plastic injection mold manufacturing Before injection molding, mold processing manufacturers need to go through a detailed mold production design process. In recent years, the requirements for precision mold design have become increasingly higher. When designing molds, plastic injection mold manufacturers must use automated design programming and supporting tools to improve the […]

Tag Archives: custom plastic injection mold for bluetooth earphone

Bubble and vacuum bubble defects refer to defects in PPSU medical injection molding products caused by the slowest cooling at the center of the product wall thickness and rapid cooling on the surface. The rapidly shrinking surface will pull the material over, causing uneven shrinkage of the product volume and causing voids in the thickness […]

Color change of medical injection molding products, also known as color streaks, refers to the phenomenon that the color of the injection molded product is inconsistent with the standard color. The following is the analysis and troubleshooting methods of color change and color streaks: 1. The quality of the colorant does not meet the requirements […]

Flow marks are common surface defects of plastic parts near the gate, which appear as a wavy mark and present a concentric circle centered on the gate. Flow marks are usually caused by uneven temperature distribution of plastic parts during the molding process or too fast plastic solidification. In addition, during the melt flow process, […]