Section 1: The Art of Sheet Metal Fabrication

Sheet metal fabrication is a complex process that involves cutting, bending, and shaping metal sheets into desired forms. It finds applications in industries such as automotive, aerospace, construction, and electronics. The process typically includes steps like shearing, forming, welding, and finishing. By mastering these techniques, manufacturers can create precise and high-quality metal products.

Section 2: Unparalleled Product Offerings

When it comes to sheet metal fabrication, one company stands out for its exceptional product range. Their commitment to excellence, attention to detail, and innovative approaches have earned them a reputable position in the industry. Let’s delve into some of their key product offerings and understand the advantages they bring to the table.

2.1 Product A: Versatile and Durable Fabrication Solution

Product A is a versatile sheet metal fabrication solution designed to meet the diverse needs of various industries. Its key features include:

- Material options: Aluminum, stainless steel, mild steel, and more

- Precision cutting: Laser cutting and CNC punching for accurate shapes and sizes

- Robust welding techniques: TIG, MIG, and spot welding for superior joint strength

- Surface finishing: Powder coating, anodizing, and plating for enhanced durability and aesthetics

2.2 Product B: Customization at Its Best

Product B is tailored to meet the unique requirements of clients. Its standout advantages include:

- Custom designs: Ability to create intricate shapes and sizes based on customer specifications

- Advanced software: Utilizing CAD/CAM software for precise design and efficient production

- Quality control: Stringent quality checks at each stage to ensure flawless end products

- Quick turnaround: Efficient production processes to deliver products within tight deadlines

Section 3: Advantages and Characteristics

The products offered by this reputable company possess several advantages and characteristics that set them apart from the competition. Let’s take a closer look:

3.1 Superior Quality

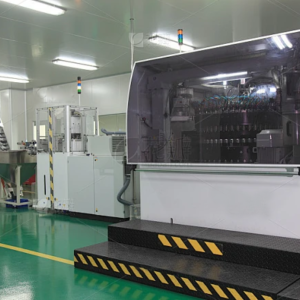

The company prides itself on delivering products of exceptional quality. By utilizing state-of-the-art machinery, skilled professionals, and rigorous quality control measures, they ensure that each fabricated component meets the highest industry standards.

3.2 Precision and Accuracy

Precision is paramount in sheet metal fabrication, and this company excels in delivering accurate products. With advanced cutting and forming techniques, they can achieve intricate designs and tight tolerances, ensuring seamless integration with other components.

3.3 Durability and Reliability

Durability is a key characteristic of the company’s products. By employing robust welding techniques and high-quality materials, they ensure that the fabricated components can withstand demanding environments and provide long-lasting performance.

3.4 Cost-Effectiveness

Despite the superior quality and advanced features, the company’s products offer excellent cost-effectiveness. By optimizing production processes and leveraging economies of scale, they can provide competitive pricing without compromising on quality.

Table 1: Sheet Metal Fabrication Parameters

— | — | —

Material | Aluminum, Stainless Steel, Mild Steel | ISO 9187

Cutting Accuracy | ±0.1mm | ISO 9013

Welding Strength | ≥60% of Parent Material Strength | AWS D1.1

Surface Finish | Powder Coating, Anodizing, Plating | ISO 1462

Sheet metal fabrication is a vital process that requires expertise and precision. The company discussed has proven its excellence in delivering top-notch products that cater to the diverse needs of various industries. With their commitment to quality, precision, durability, and cost-effectiveness, their product offerings are a cut above the rest. By choosing their sheet metal fabrication solutions, businesses can expect superior performance, reliability, and a competitive edge in their respective domains.

Reviews

There are no reviews yet.