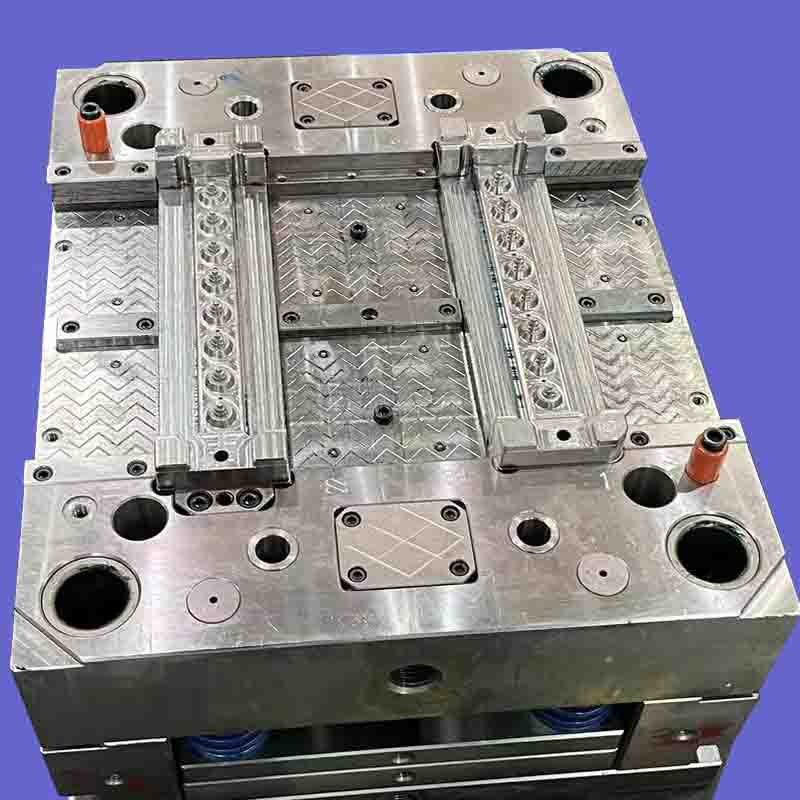

1. Precision injection molding

Precision injection molding technology can ensure that the product has high precision and high repeatability in terms of size and weight. The injection molding machine using this technology can achieve high-pressure and high-speed injection. Since its control method is usually open-loop or closed-loop control, the injection molding process parameters can be controlled with high precision. Precision injection molding has high requirements on the precision of the mold. At present, small and medium-sized precision injection molding machines can be produced in China.

2. Rapid prototyping technology

With the diversification and continuous updating of household appliances, rapid prototyping technology has emerged, which is mainly used to prepare plastic housings for household appliances. The advantage of this technology is that it can achieve small-batch production of plastic parts without molds. At present, mature rapid prototyping methods include laser scanning molding and liquid light curing molding, among which laser scanning molding is widely used. The laser scanning equipment consists of a laser light source, a scanning device, a powder spreading device and a computer. The computer controls the laser head to scan along a certain trajectory. The plastic micropowder is heated and melted and bonded together. After repeated scanning, a product with a specific shape and size is formed. At present, some domestic charger shell manufacturers have been able to produce laser scanning molding machines and plastic micropowders, but the equipment performance is still unstable and the variety of micropowders is also relatively small.

3. Melt core injection molding technology

Melted core injection molding technology is suitable for molding special-shaped cavity products with high requirements for cavity roughness and precision, especially products that cannot be processed by hollow molding or rotational molding. At present, this technology is more mature in foreign countries, but it is still in the stage of individual application in China. Its processing principle is to first mold the core mold that constitutes the cavity, and then use the core mold as an insert for injection molding. Under the heating action of the injection molded part, the core mold melts and flows out to form a cavity. When using this technology, it is necessary to understand the melting points of the core material and the plastic part. Generally, general plastics, thermoplastic elastomers or low melting point metals (such as lead, tin, etc.) can be selected.

4. Gas-assisted/water-assisted injection molding

Gas-assisted/water-assisted injection molding technology is widely used and can form various types of injection molded parts. Typical products include TV shells. During the injection molding process, gas or superheated water and plastic melt are almost simultaneously injected into the mold cavity. The plastic melt envelops the gas or superheated water, and the molded plastic product is a sandwich structure. After the plastic part is shaped, the gas or water can be discharged to demold. This type of product has the advantages of saving material, small shrinkage, good appearance and strong rigidity. The key part of the molding equipment is the gas-assisted or water-assisted device and its control software. In recent years, although the research and application of this technology in China has been rapid, the stability of domestic equipment still needs to be improved.

5. Electromagnetic dynamic injection molding technology

Electromagnetic dynamic injection molding technology was invented by Mr. Qu Jinping of South China University of Technology. This technology uses electromagnetic force to make the screw reciprocate in the axial direction. In the pre-plasticization stage, the plastic is micro-plasticized, so that the plastic part structure in the pressure holding stage is tighter and the internal stress of the product is reduced. This technology is suitable for products with high molding requirements, such as CDs, and can also improve the quality of products in the molding of ordinary products.

6. Film injection molding technology

Film injection molding technology has been relatively maturely applied abroad. When using this technology, a special printed decorative plastic film needs to be clamped in the mold before injection molding, and then injection molding is performed. The printed film deforms after being heated and can be firmly attached to the surface of the plastic part, which is not only beautiful but also saves the subsequent decoration steps.

Reviews

There are no reviews yet.