HDPE plastic injection molding has become a vital process in the manufacturing industry, offering versatility, durability, and cost-effectiveness. With the increasing demand for high-quality HDPE products, it is crucial for manufacturers to choose the right partner to ensure optimal performance and reliability. In this article, we will delve into a case study of our company’s HDPE plastic injection molding products, highlighting their advantages, unique features, and how they have revolutionized the industry.

Case Study: A Successful Project for a Leading Retailer

One of our recent projects involved manufacturing a wide range of HDPE containers for a leading retailer. The client required a high-volume, cost-effective solution that could withstand harsh environmental conditions and meet stringent quality standards. Our team of experts designed and produced a customized HDPE injection molding solution that exceeded the client’s expectations.

Advantages of Our HDPE Plastic Injection Molding Products

Material Quality

Our HDPE plastic injection molding products are manufactured using high-grade raw materials, ensuring superior strength, durability, and resistance to chemicals, UV rays, and temperature fluctuations. The material quality is guaranteed to meet the highest industry standards, providing long-lasting performance.

Customization

We offer a wide range of customization options to cater to our clients’ specific requirements. Our in-house design team works closely with clients to develop tailored HDPE products that meet their unique specifications, including size, shape, color, and texture.

Cost-Effectiveness

Our HDPE plastic injection molding process is highly efficient, enabling us to offer competitive pricing without compromising on quality. By optimizing our production processes and leveraging advanced technology, we provide cost-effective solutions that help our clients achieve their business goals.

Quick Turnaround Time

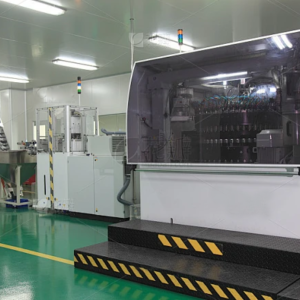

We understand the importance of time in the manufacturing industry. Our state-of-the-art facilities and experienced team ensure quick turnaround times, allowing us to meet tight deadlines and keep projects on track.

Environmentally Friendly

Our HDPE plastic injection molding products are eco-friendly, as HDPE is a recyclable material. By choosing our products, clients can contribute to reducing their carbon footprint and promoting sustainability.

Table: Comparison of Our HDPE Plastic Injection Molding Products with Competitors

| Criteria | Our Products | Competitor A | Competitor B |

|---|---|---|---|

| Material Quality | High-grade HDPE | Standard HDPE | Standard HDPE |

| Customization | Tailored solutions | Limited options | Limited options |

| Cost-Effectiveness | Competitive pricing | Higher pricing | Higher pricing |

| Turnaround Time | Quick turnaround | Average turnaround | Average turnaround |

| Environmental Impact | Eco-friendly | Non-recyclable | Non-recyclable |

Unique Features of Our HDPE Plastic Injection Molding Products

- Advanced Injection Molding Technology

Our company invests in the latest injection molding technology, ensuring precise and efficient production processes. This allows us to create complex HDPE products with tight tolerances and superior surface finish.

- In-House Design and Engineering

Our team of experienced designers and engineers works closely with clients to develop innovative HDPE solutions. This collaborative approach ensures that our products meet the highest quality standards and exceed client expectations.

- Quality Control

We maintain a rigorous quality control process throughout the production cycle, ensuring that every HDPE product meets our stringent standards. This commitment to quality has earned us a reputation for delivering reliable and durable products.

Our company’s HDPE plastic injection molding products have revolutionized the industry by offering high-quality, customizable, and cost-effective solutions. With a focus on material quality, customization, and sustainability, we have become a preferred partner for leading retailers and manufacturers. By choosing our products, clients can expect superior performance, reliability, and a competitive edge in their respective markets.

Reviews

There are no reviews yet.