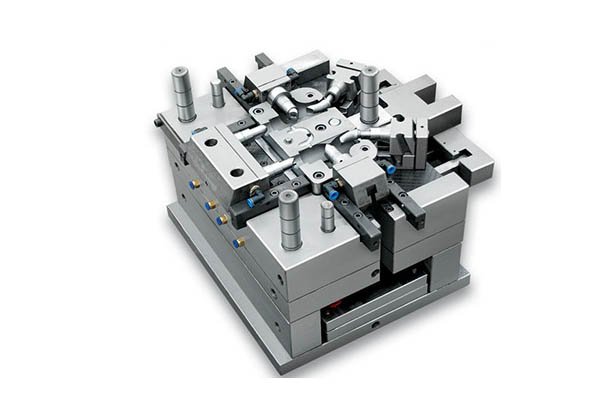

Medical Double-Color Plastic Injection Molding Companies Manual operation is for machine adjustment and maintenance; semi-automatic operation is for injection molding fragile, easily scratched and long products; fully automatic operation is for high-speed production, injection molding precision products, and can reduce the workload of operators. Locking part: 1. Install the moldA. Measure the mold thickness and […]

Author Archives: sing-oi

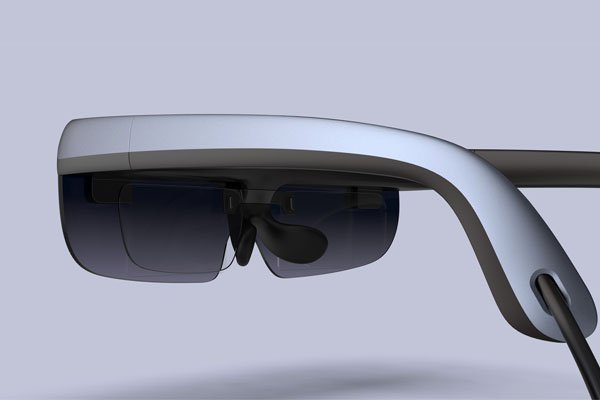

1. AR Glasses Injection Molding Products formation of white lines 1.1 Microscopic explanation of white lines: When plastic is subjected to tensile stress, cavitation stripe-shaped deformation areas are generated due to stress concentration. These stripe plane areas strongly reflect visible light, forming a silver-white luster on the surface of the material, commonly known as white lines. […]

The defects are roughly as follows: (i) Silver streaks: Due to the anisotropy of internal stress during mold filling and condensation, the stress generated in the vertical direction causes the resin to be oriented in the flow direction, and the refractive index is different from the non-flow orientation, resulting in flash streaks. When it expands, […]

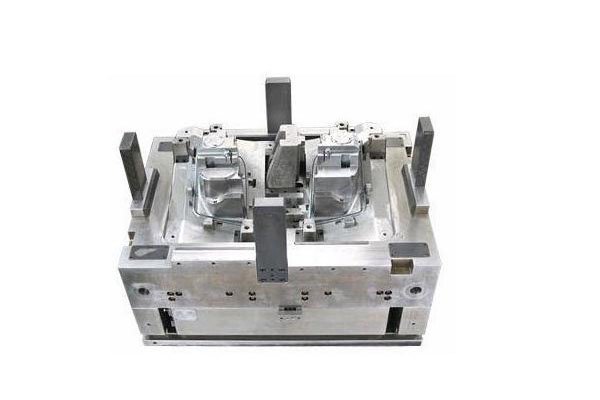

Most of the parts on the interior and exterior of the center console injection molding. The interior plastic parts generally include instrument panel accessories, seat accessories, floor accessories, roof accessories, steering wheel accessories, door interior accessories, rearview mirrors and various buckles and fixings; the exterior plastic parts include front and rear lights, air intake grilles, […]

I. Causes of dents in medical injection molding products 1. Different thicknesses of different parts of the product 2. Insufficient internal pressure of the mold 3. Insufficient cooling of the mold 4. Deformation caused by insufficient cooling time II. Related knowledge 1. In the process of producing products, dents are the most frequent defective phenomenon. […]

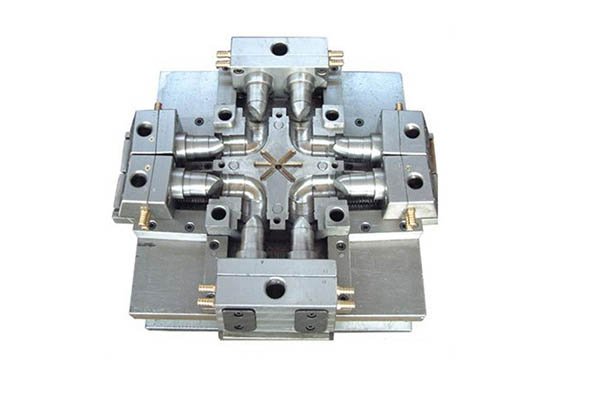

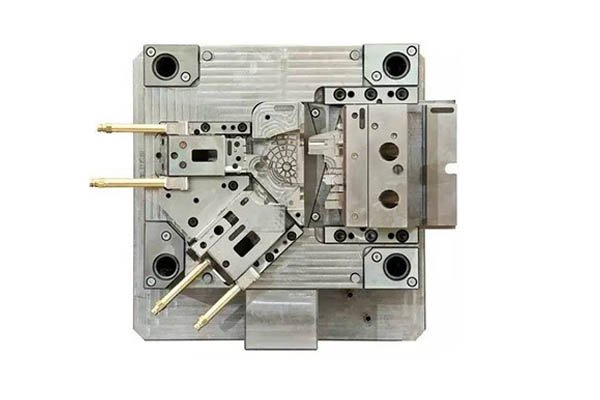

Plastic Injection Molding Overmolding Cold runner refers to the part between the mold entrance and the product gate. Plastics in the runner are kept flowing by injection pressure and its own heat. The runner is part of the molding material, but it does not belong to the product. Therefore, when we design the mold, we […]

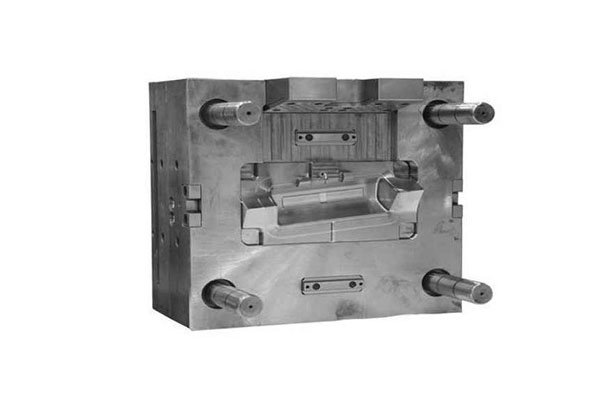

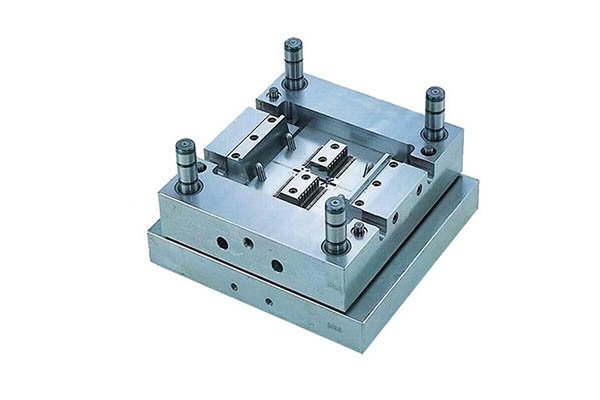

Injection molds should be tested for various properties of the mold under normal operation of the injection molding machine and mold, and the dimensions of the final molded plastic parts should be measured. This information can be used to determine the current state of the mold, find out where the cavity, core, cooling system and […]

For injection molded parts, shrinkage and whitening are generally a pair of conflicting problems. Usually, part shrinkage is caused by low cavity pressure and insufficient injection of parts. And top whitening is usually caused by high cavity pressure and over-injection. Logically, this pair of happy enemies should be mortal enemies and never get along with […]

I. Injection mold 1. Poor mold cavity processing If the mold cavity has scars, micropores, wear, roughness and other deficiencies, it will inevitably reflect on the plastic parts, making the plastic parts have poor gloss. For this, the mold should be carefully processed to make the surface of the cavity have a smaller roughness, and […]

For an Electronic product shell processing factory, the energy consumption of the injection molding process accounts for about 60%, so effectively reducing the energy consumption of injection molding machines is an important way to save energy in injection molding factories. With the continuous improvement of the energy-saving technology of injection molding machines themselves, reducing the […]