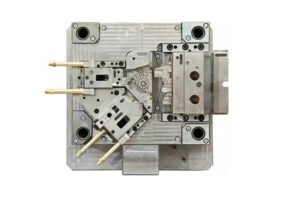

I. Injection mold

1. Poor mold cavity processing

If the mold cavity has scars, micropores, wear, roughness and other deficiencies, it will inevitably reflect on the plastic parts, making the plastic parts have poor gloss. For this, the mold should be carefully processed to make the surface of the cavity have a smaller roughness, and chrome plating can be polished if necessary.

2. Stains on the surface of the cavity

If there are oil stains, water stains on the surface of the cavity, or too much release agent, the surface of the plastic parts will be dark and dull. For this, the oil stains and water stains should be removed in time, and the release agent should be used in limited quantities.

3. The demolding slope of the plastic part is too small

If the demolding slope is too small, it will cause demolding difficulties, or the force during demolding is too large, making the surface gloss of the plastic parts the best. For this, the demolding slope should be increased.

4. Poor mold exhaust

If the exhaust is poor, too much gas will remain in the model, which will also cause poor gloss. For this, the mold exhaust system should be checked and corrected.

5. Improper gate or runner design

The gate or runner cross-sectional area is too small or changes suddenly. The melt is subjected to too much shear force when flowing in it, and flows in a turbulent dynamic flow, resulting in poor gloss. For this, the gate and runner cross-sectional area should be appropriately increased.

2. Injection molding process

1. The injection speed is too low

The injection speed is too low, resulting in a loose surface of the plastic part and poor gloss. For this, the injection speed can be appropriately increased.

2. Insufficient cooling of plastic parts

For example, if the cooling of thick-walled plastic parts is insufficient, the surface will be hairy and the gloss will be dark. For this, the cooling system should be improved.

3. Improper holding pressure operation

If the holding pressure is too small and the holding time is too short, the density of the plastic part is insufficient and the gloss is poor. For this, the holding pressure and holding time should be increased.

4. If the melt temperature is too low

When the melt flow is too low, the fluidity is poor, which is easy to cause poor gloss. For this, the melt temperature should be appropriately increased.

5. Uneven cooling of crystalline resin

For plastic parts made of PE, PP, POM, etc., uneven cooling will lead to poor gloss. For this, the cooling system should be improved to make it cool evenly.

6. Injection speed and gate area do not match

If the injection speed is too high and the gate cross-sectional area is too small, the area near the gate will be dark and the gloss will be poor. For this, the injection speed can be appropriately reduced and the gate cross-sectional area can be increased.

III. Raw materials

1. Large differences in raw material particle size

The large difference in particle size makes it difficult to plasticize evenly, and the gloss is poor. For this, the raw materials should be screened.

2. Too much secondary material in the raw material

If too much recycled material or nozzle material is added, it will affect the uniform plasticization of the melt and the gloss will be poor. For this, the amount of recycled material or nozzle material added should be reduced.

3. Poor temperature resistance of raw materials

Some raw materials will decompose and discolor during temperature adjustment, resulting in poor gloss. For this, raw materials with better temperature resistance should be selected.

4. The raw materials contain volatile substances

If the moisture or volatile content in the raw materials is too high, it will volatilize into gas when heated, condense in the cavity and melt, and cause the plastic parts to have poor gloss. For this, the raw materials should be pre-dried.

5. The dispersion of additives is not good

Some additives have poor dispersion and make the plastic parts have poor gloss. For this, additives with better flow properties should be used instead.

6. The raw materials are impure

If the raw materials are mixed with foreign matter, miscellaneous materials or incompatible materials, they cannot be evenly mixed with the raw materials and cause poor gloss. For this, these miscellaneous materials should be strictly excluded in advance.

7. Too little lubricant

If the lubricant is too little, the melt has poor fluidity, the surface of the plastic part is not dense, and the gloss is poor. For this, the amount of lubricant should be appropriately increased.

Therefore, it also depends on whether your mold polishing degree meets the requirements. If there is no problem with the mold itself, it is necessary to determine the characteristics of your ABS. You can choose high mold temperature, high speed and high pressure; using chilled water can also achieve smoothness.