Injection molding

Injection molding is a common plastic molding method that involves injecting molten plastic material into a mold and forming the desired finished product after cooling and solidification. This method is suitable for manufacturing plastic products of various shapes and sizes, from simple daily necessities to complex industrial parts.

Overmolding

Overmolding is a special molding technology that can achieve the combination of different materials. Depending on the material, overmolding can be divided into “plastic in plastic”, “soft plastic in plastic” and “soft plastic in soft plastic”. This technology can not only enhance the functionality and aesthetics of the product, but also improve the durability and service life of the product.

How to achieve overmolding

Overmolding can be achieved through physical and chemical methods:

Physical method: Use snap-fit design, surface tapping, etc. to make the two materials fit tightly. This method mainly relies on mechanical connection, and the physically connected part has strong adhesion, while the non-connected part has weak adhesion.

Chemical method: The two materials are firmly combined together through the affinity or chemical bond between molecules. This method can form a whole and ensure the close combination between the two materials, thereby improving the overall performance of the product.

Insert molding

Insert molding is a special form of injection molding in which metal or other hard materials are pre-placed in the mold as inserts. These inserts can be made of brass, steel or stainless steel, and usually have a threaded design to better combine with the plastic material. Insert molding technology is widely used in production areas that require high-strength and high-precision parts, such as the automotive, electronics and medical device industries.

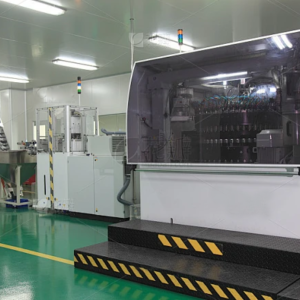

During the insert molding process, the insert is usually placed manually or by automated equipment into the mold to ensure its precise alignment. As the molten plastic is injected, it gradually wraps around the insert to form the final product. The use of advanced vertical injection molding machines and strict quality control processes can ensure that insert molding products meet extremely high precision standards.

Whether it is insert molding or overmolding, it provides more diverse solutions for plastic products and meets the diverse needs of different industries.

Reviews

There are no reviews yet.