Dimensional instability refers to the change in the size of plastic parts between each batch of router injection molding products or between each cavity product produced by each mold under the same injection molding machine and molding process conditions. Fluctuations in product size are usually caused by abnormal equipment control, unreasonable injection molding conditions, product […]

Tag Archives: Router Injection Molding Products

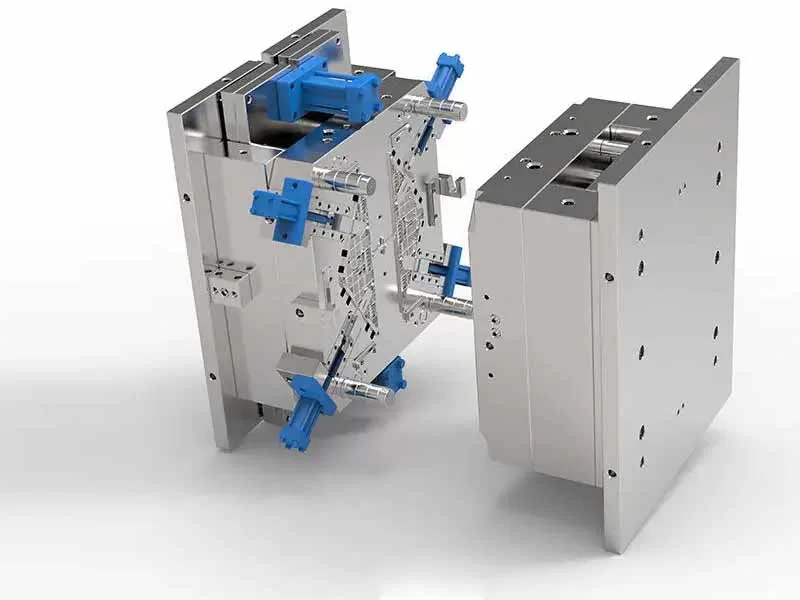

Router Injection Molding Products poor demolding, also known as die adhesion, occurs when sprues or molded parts stick to the mold, often due to inadequate contact between the injection port and the nozzle arc, incomplete removal of gate material, or abnormal filler conditions. The main runner diameter must be sufficiently large to ensure that the […]

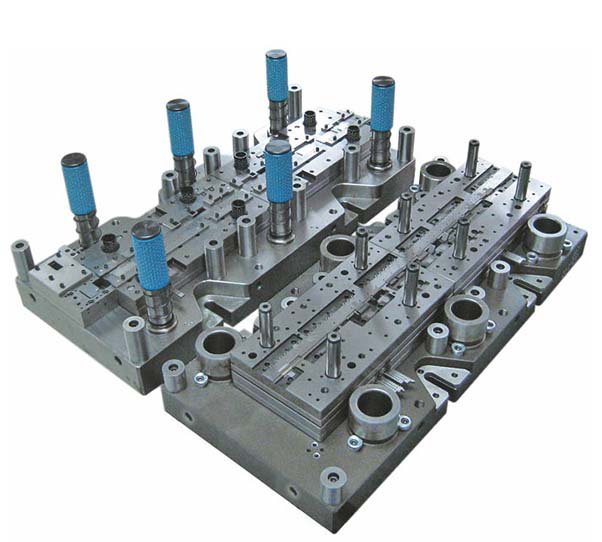

Router Injection Molding Products flash is also called overflow, burr, etc. It mostly occurs at the parting position of the mold, such as the parting surface of the dynamic mold and the static mold, the sliding part of the slider, the gap of the insert, the hole of the ejector pin, etc. Flash is largely […]

This standard mainly stipulates the inspection and test methods of various plastic products produced by injection molding. It is applicable to the inspection of general HDPE Plastic Injection Molding Manufacturer. This standard is only for routine inspection. Special requirements shall be subject to PARTSPEC. Explanation of common defects 1 Scorch marks (RURNS): material decomposition caused […]

Waves or grooves are common defects in Router Injection Molding Products. Generally, the surface defects caused by the pause of the flow peak due to insufficient injection pressure or reduced injection speed are the result of stress induction of the product. Different surface defect forms have different causes. Exploring these causes and avoiding them is […]

I. Causes of dents in medical injection molding products 1. Different thicknesses of different parts of the product 2. Insufficient internal pressure of the mold 3. Insufficient cooling of the mold 4. Deformation caused by insufficient cooling time II. Related knowledge 1. In the process of producing products, dents are the most frequent defective phenomenon. […]

For injection molded parts, shrinkage and whitening are generally a pair of conflicting problems. Usually, part shrinkage is caused by low cavity pressure and insufficient injection of parts. And top whitening is usually caused by high cavity pressure and over-injection. Logically, this pair of happy enemies should be mortal enemies and never get along with […]

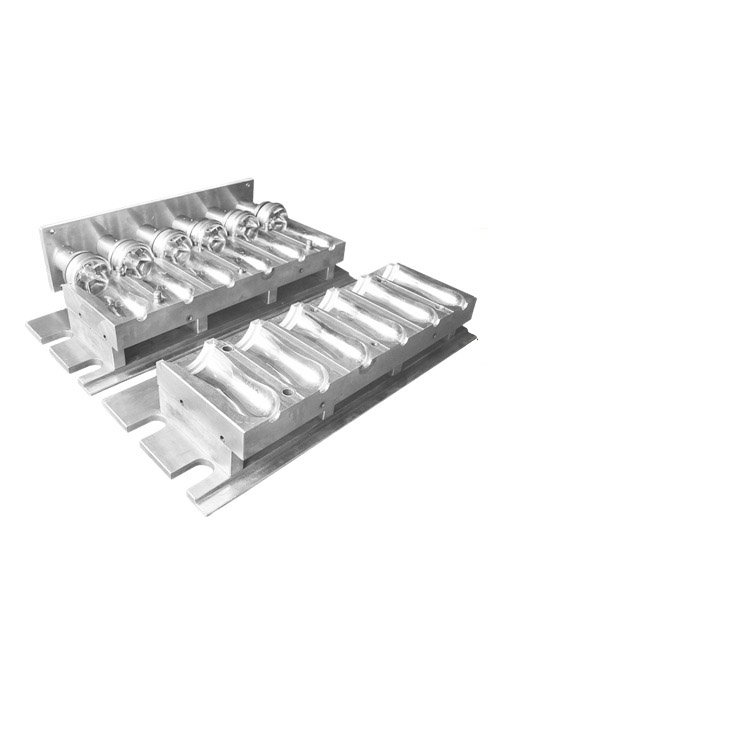

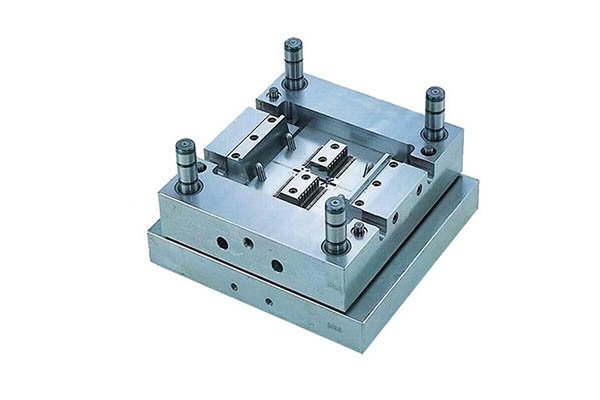

Understanding the Estimation of Injection Mold Prices Estimating the cost of an injection mold involves several key steps to ensure accuracy and transparency for both plastic injection molding Manufacturer and the customer. Here’s a breakdown of the process: Material Selection and Manufacturing Process: The first step is to select the appropriate steel and manufacturing process […]

Plastic injection molding transforms melted pellets into solid plastic products through high-pressure injection into molds. This process is invaluable for creating items with complex shapes, widely used in automotive, medical, electronics, and packaging industries. Canada’s plastic injection molding sector has grown significantly, supported by companies known for their expertise and innovation. Brief introduction of each […]