Bubble and vacuum bubble defects refer to defects in PPSU medical injection molding products caused by the slowest cooling at the center of the product wall thickness and rapid cooling on the surface. The rapidly shrinking surface will pull the material over, causing uneven shrinkage of the product volume and causing voids in the thickness […]

Tag Archives: PPSU Medical Injection Molding Products

Silver streaks refer to splash marks formed on the surface of plastic parts, usually caused by the volatilization of air and moisture in the plastic, or the decomposition and burning of foreign plastics after mixing. These marks usually radiate outward from the gate in a fan-shaped manner. Many plastics absorb moisture during storage. If they […]

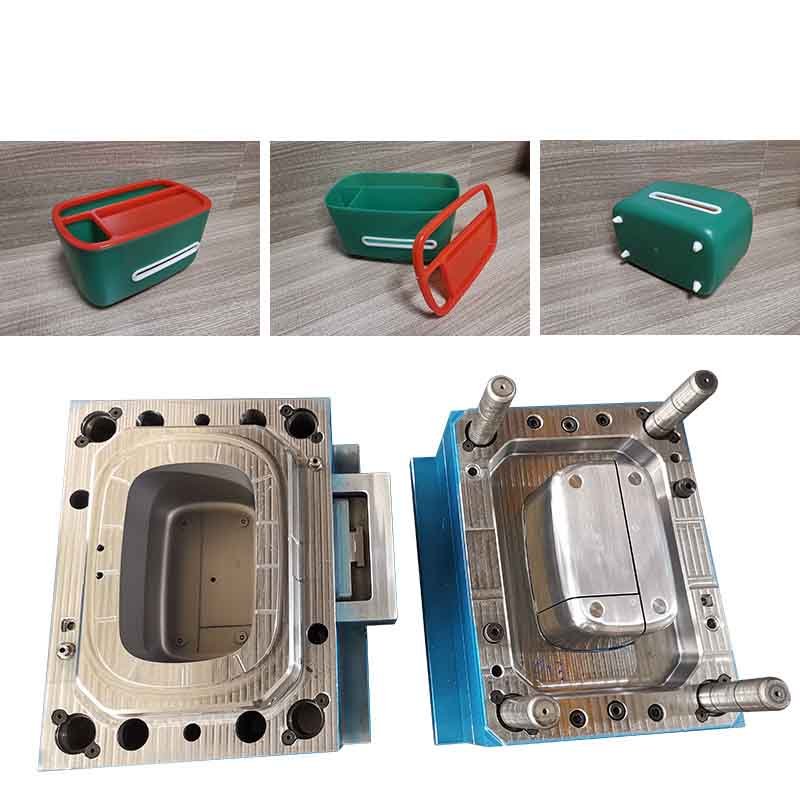

Medical Double-Color Plastic Injection Molding Companies has established standards for mold approval from three aspects: mold structure, plastic part quality, and injection molding process requirements. Based on this, the mold quality is evaluated and scored, hoping to continuously improve the mold quality; ensure that the mold can be put into production normally and produce plastic […]

Waves or grooves are common defects in Router Injection Molding Products. Generally, the surface defects caused by the pause of the flow peak due to insufficient injection pressure or reduced injection speed are the result of stress induction of the product. Different surface defect forms have different causes. Exploring these causes and avoiding them is […]

Medical Double-Color Plastic Injection Molding Companies Manual operation is for machine adjustment and maintenance; semi-automatic operation is for injection molding fragile, easily scratched and long products; fully automatic operation is for high-speed production, injection molding precision products, and can reduce the workload of operators. Locking part: 1. Install the moldA. Measure the mold thickness and […]

I. Causes of dents in medical injection molding products 1. Different thicknesses of different parts of the product 2. Insufficient internal pressure of the mold 3. Insufficient cooling of the mold 4. Deformation caused by insufficient cooling time II. Related knowledge 1. In the process of producing products, dents are the most frequent defective phenomenon. […]

For injection molded parts, shrinkage and whitening are generally a pair of conflicting problems. Usually, part shrinkage is caused by low cavity pressure and insufficient injection of parts. And top whitening is usually caused by high cavity pressure and over-injection. Logically, this pair of happy enemies should be mortal enemies and never get along with […]