Plastic Injection Molding Overmolding Cold runner refers to the part between the mold entrance and the product gate. Plastics in the runner are kept flowing by injection pressure and its own heat. The runner is part of the molding material, but it does not belong to the product. Therefore, when we design the mold, we […]

Tag Archives: Medical injection molding products

I. Injection mold 1. Poor mold cavity processing If the mold cavity has scars, micropores, wear, roughness and other deficiencies, it will inevitably reflect on the plastic parts, making the plastic parts have poor gloss. For this, the mold should be carefully processed to make the surface of the cavity have a smaller roughness, and […]

High gloss and high-brightness products are indeed a difficult problem for Medical Double-Color Plastic Injection Molding Companies to deal with, because they cannot hide external defects. Even the dust in the workshop can cause defects of varying degrees in the product, such as sand eyes, pitting, stains, etc., so the environment also affects the white […]

Introduction The temperature inside the mold during center console injection molding is the most important variable in injection molding – no matter what kind of plastic, it must ensure that the mold surface is basically wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure in the cavity. If the […]

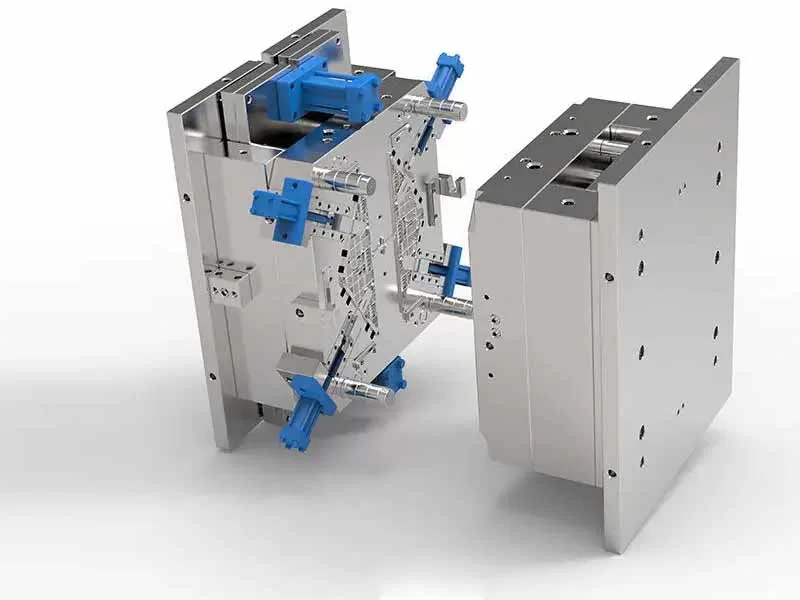

Plastic injection molding transforms melted pellets into solid plastic products through high-pressure injection into molds. This process is invaluable for creating items with complex shapes, widely used in automotive, medical, electronics, and packaging industries. Canada’s plastic injection molding sector has grown significantly, supported by companies known for their expertise and innovation. Brief introduction of each […]

- 1

- 2