Surface defects in medical injection molding products can significantly impact both the aesthetic quality and functional integrity of the final product. Common defects include cracks, silver streaks, grooves, ripples, wave marks, and embrittlement. These defects often arise from stress induced within the product, which can exceed its material strength. Understanding the causes of these defects […]

Tag Archives: Medical injection molding products

Color change of medical injection molding products, also known as color streaks, refers to the phenomenon that the color of the injection molded product is inconsistent with the standard color. The following is the analysis and troubleshooting methods of color change and color streaks: 1. The quality of the colorant does not meet the requirements […]

Analysis and solutions to uneven product color in medical injection molding products The main reasons for uneven color of injection molding products and their solutions are as follows: (1) Poor diffusion of colorants, which often causes patterns to appear near the gate. (2) Plastics or colorants have poor thermal stability. To stabilize the color of […]

abs plastic molding manufacturers before molding, plastic must be fully dried. When materials containing water enter the mold cavity, silver ribbon-like defects will appear on the surface of the product, and even hydrolysis will occur at high temperatures, causing material degradation. Therefore, the material must be pre-treated before molding so that the material can maintain appropriate […]

Medical injection molding products Because it is required to have good transparency, high wear resistance, and good impact toughness, a lot of work needs to be done on the composition of plastics, the process of the entire injection molding process, equipment, molds, etc., to ensure that these plastics used to replace glass (hereinafter referred to […]

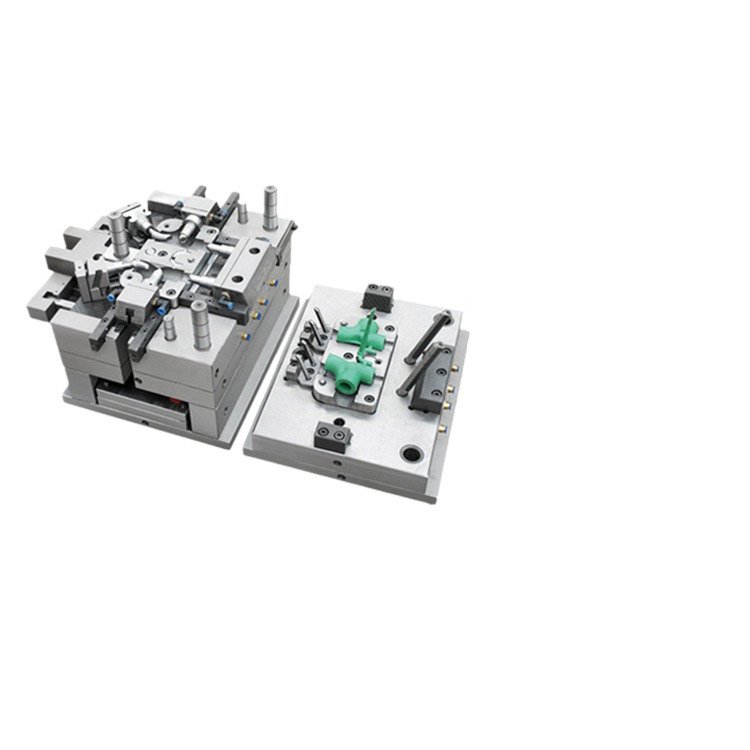

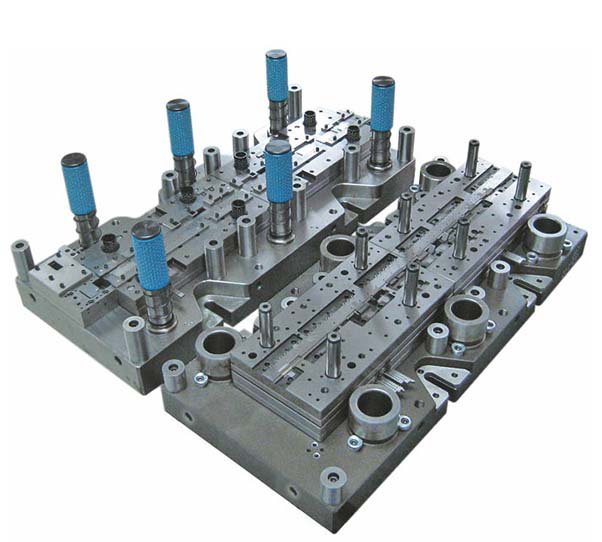

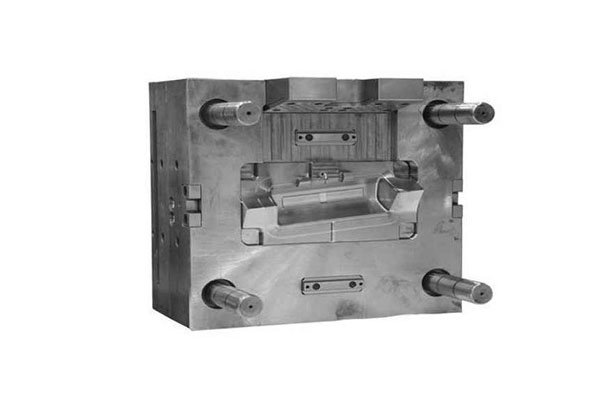

Medical Double-Color Plastic Injection Molding Companies has established standards for mold approval from three aspects: mold structure, plastic part quality, and injection molding process requirements. Based on this, the mold quality is evaluated and scored, hoping to continuously improve the mold quality; ensure that the mold can be put into production normally and produce plastic […]

Waves or grooves are common defects in Router Injection Molding Products. Generally, the surface defects caused by the pause of the flow peak due to insufficient injection pressure or reduced injection speed are the result of stress induction of the product. Different surface defect forms have different causes. Exploring these causes and avoiding them is […]

Medical Double-Color Plastic Injection Molding Companies Manual operation is for machine adjustment and maintenance; semi-automatic operation is for injection molding fragile, easily scratched and long products; fully automatic operation is for high-speed production, injection molding precision products, and can reduce the workload of operators. Locking part: 1. Install the moldA. Measure the mold thickness and […]

The defects are roughly as follows: (i) Silver streaks: Due to the anisotropy of internal stress during mold filling and condensation, the stress generated in the vertical direction causes the resin to be oriented in the flow direction, and the refractive index is different from the non-flow orientation, resulting in flash streaks. When it expands, […]

I. Causes of dents in medical injection molding products 1. Different thicknesses of different parts of the product 2. Insufficient internal pressure of the mold 3. Insufficient cooling of the mold 4. Deformation caused by insufficient cooling time II. Related knowledge 1. In the process of producing products, dents are the most frequent defective phenomenon. […]

- 1

- 2