In the process of Medical Double-Color Plastic Injection Molding Companies, whether it is a hydraulic or electric injection molding machine, all the movements during the injection process will generate pressure. Proper control of the required pressure is the key to producing high-quality finished products. Pressure Control and Metering System In a hydraulic injection molding machine, […]

Tag Archives: Medical Double-Color Plastic Injection Molding Companies

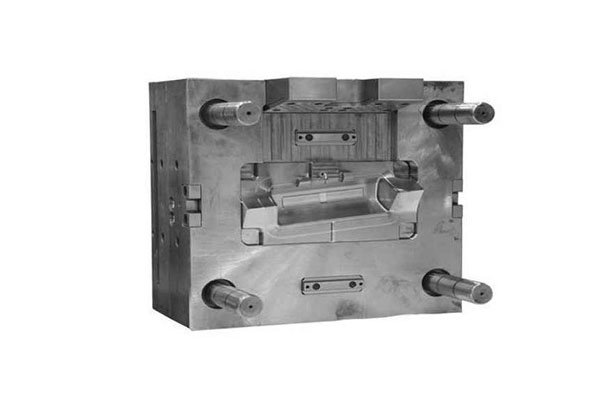

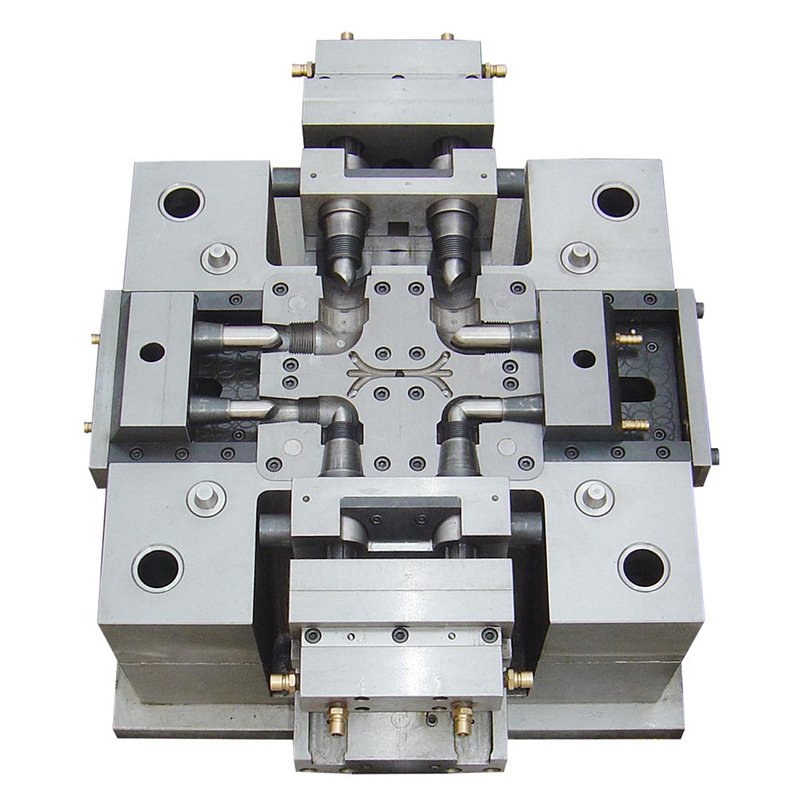

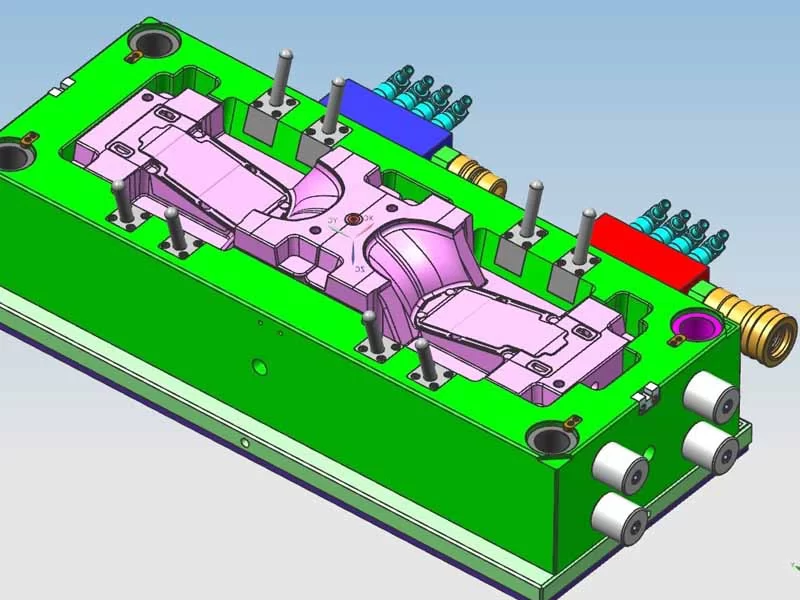

Medical Double-Color Plastic Injection Molding Companies and overmolding are two common injection molding processes. Although they both involve multiple molding of two plastic materials, there are differences in specific operation methods and mold design. Two-color mold Two-color mold refers to using the same injection molding machine to mold twice on the same set of molds, […]

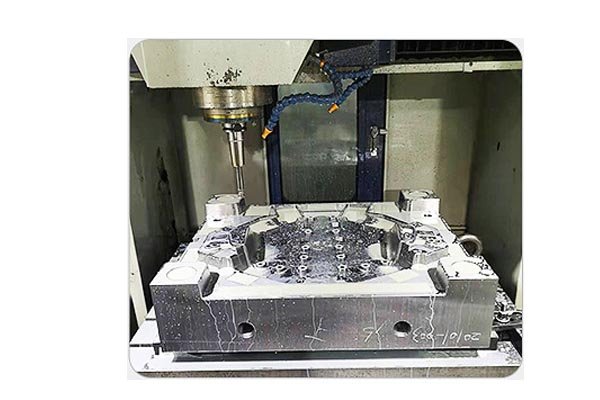

Medical Double-Color Plastic Injection Molding Companies has established standards for mold approval from three aspects: mold structure, plastic part quality, and injection molding process requirements. Based on this, the mold quality is evaluated and scored, hoping to continuously improve the mold quality; ensure that the mold can be put into production normally and produce plastic […]

Medical Double-Color Plastic Injection Molding Companies Manual operation is for machine adjustment and maintenance; semi-automatic operation is for injection molding fragile, easily scratched and long products; fully automatic operation is for high-speed production, injection molding precision products, and can reduce the workload of operators. Locking part: 1. Install the moldA. Measure the mold thickness and […]

The defects are roughly as follows: (i) Silver streaks: Due to the anisotropy of internal stress during mold filling and condensation, the stress generated in the vertical direction causes the resin to be oriented in the flow direction, and the refractive index is different from the non-flow orientation, resulting in flash streaks. When it expands, […]

Plastic Injection Molding Overmolding Cold runner refers to the part between the mold entrance and the product gate. Plastics in the runner are kept flowing by injection pressure and its own heat. The runner is part of the molding material, but it does not belong to the product. Therefore, when we design the mold, we […]

High gloss and high-brightness products are indeed a difficult problem for Medical Double-Color Plastic Injection Molding Companies to deal with, because they cannot hide external defects. Even the dust in the workshop can cause defects of varying degrees in the product, such as sand eyes, pitting, stains, etc., so the environment also affects the white […]

Understanding the Estimation of Injection Mold Prices Estimating the cost of an injection mold involves several key steps to ensure accuracy and transparency for both plastic injection molding Manufacturer and the customer. Here’s a breakdown of the process: Material Selection and Manufacturing Process: The first step is to select the appropriate steel and manufacturing process […]

Factor 1: When plastic is injected into a large cavity under high pressure, melt fracture is very likely to occur. At this time, transverse fractures appear on the surface of the melt, and the fracture area is roughly mixed in the surface of the plastic part to form a burnt spot. Especially when a small […]