During the injection molding process of HDPE plastic, dent phenomenon is a common and troubling problem, which usually occurs after the gate is closed or due to local internal shrinkage caused by insufficient injection. Dents appear as depressions or tiny depressions formed on the surface of injection molded products, which are mainly caused by multiple […]

Tag Archives: HDPE Plastic Injection Molding Manufacturer

Router Injection Molding Products poor demolding, also known as die adhesion, occurs when sprues or molded parts stick to the mold, often due to inadequate contact between the injection port and the nozzle arc, incomplete removal of gate material, or abnormal filler conditions. The main runner diameter must be sufficiently large to ensure that the […]

This standard mainly stipulates the inspection and test methods of various plastic products produced by injection molding. It is applicable to the inspection of general HDPE Plastic Injection Molding Manufacturer. This standard is only for routine inspection. Special requirements shall be subject to PARTSPEC. Explanation of common defects 1 Scorch marks (RURNS): material decomposition caused […]

High gloss and high-brightness products are indeed a difficult problem for Medical Double-Color Plastic Injection Molding Companies to deal with, because they cannot hide external defects. Even the dust in the workshop can cause defects of varying degrees in the product, such as sand eyes, pitting, stains, etc., so the environment also affects the white […]

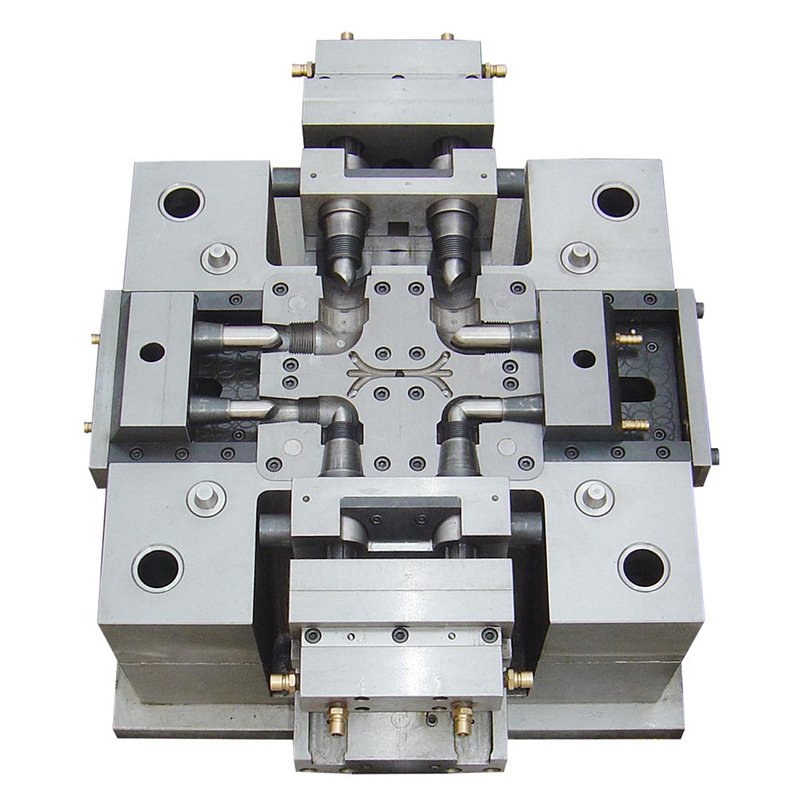

HDPE Plastic Injection Molding Manufacturer set the starting position of mold protection, anything in the mold may be damaged. In addition to the injection molding machine itself, the second most expensive equipment we use daily is the mold. When the mold is damaged, you not only have to bear the cost of repair, but also the […]