Introduction The temperature inside the mold during center console injection molding is the most important variable in injection molding – no matter what kind of plastic, it must ensure that the mold surface is basically wet. A hot mold surface keeps the plastic surface liquid long enough to build pressure in the cavity. If the […]

Category Archives: Plastic Injection Molding

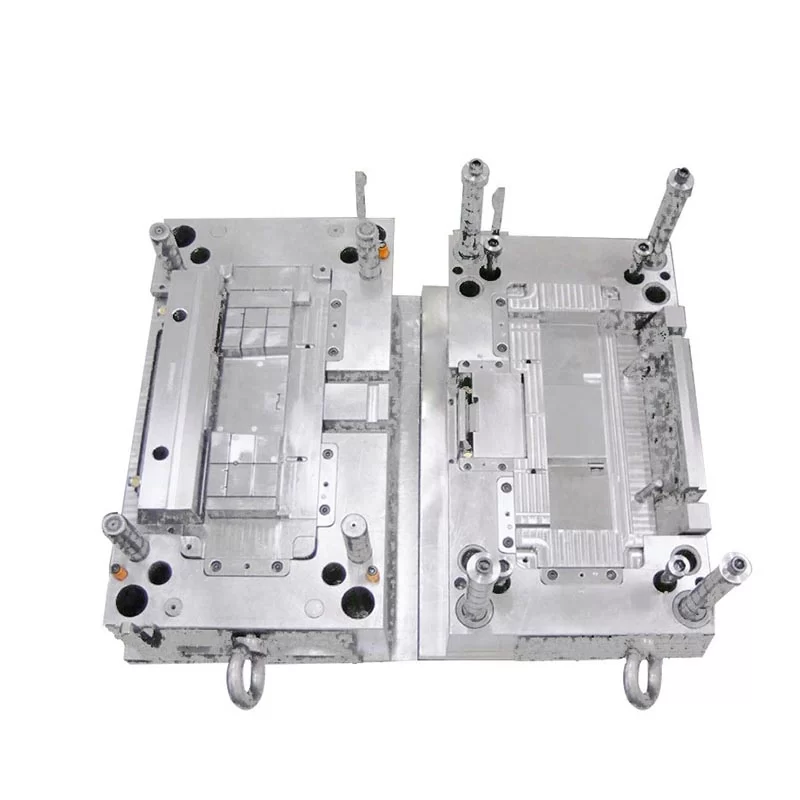

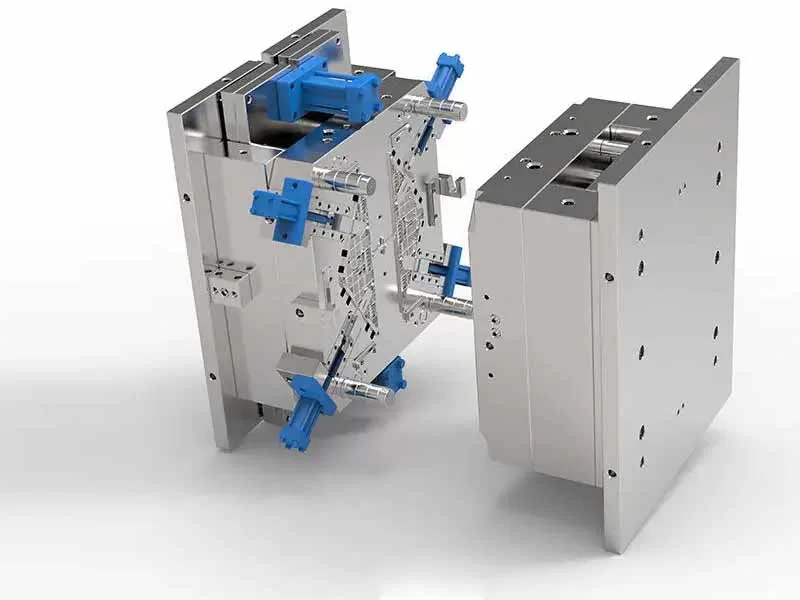

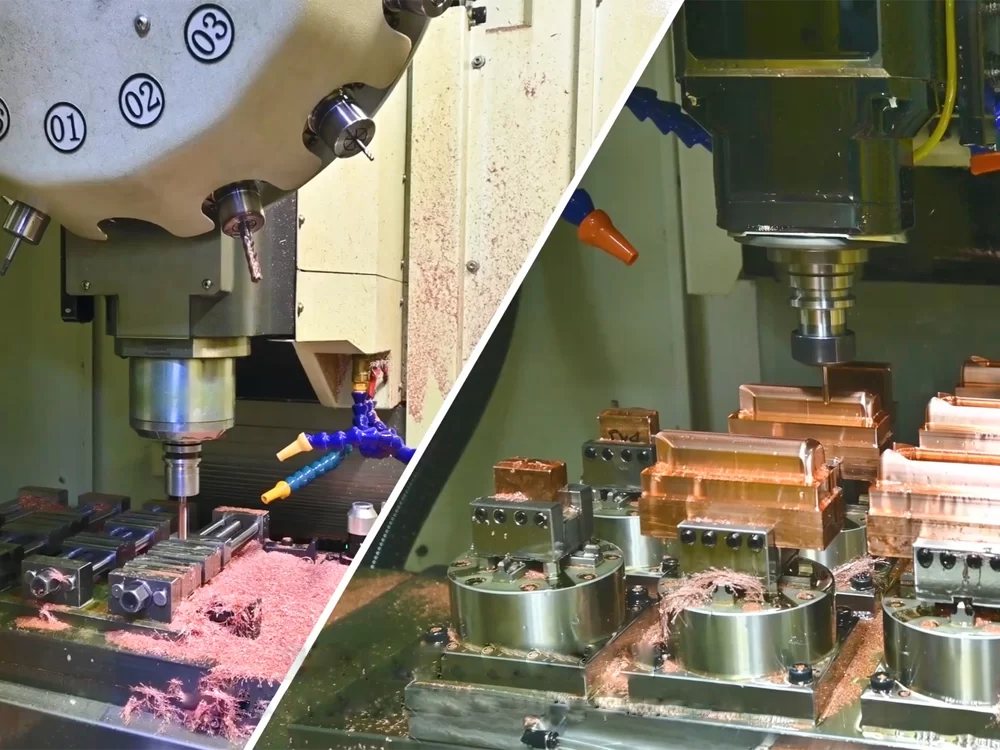

Plastic injection molding transforms melted pellets into solid plastic products through high-pressure injection into molds. This process is invaluable for creating items with complex shapes, widely used in automotive, medical, electronics, and packaging industries. Canada’s plastic injection molding sector has grown significantly, supported by companies known for their expertise and innovation. Brief introduction of each […]

Introduction With the continuous improvement of Automobile injection molding technology, it is imperative to minimize the shrinkage problem of plastic injection molding and improve product quality. Solution The shrinkage formed in the thicker parts of plastic injection molding parts, such as ribs or protrusions, is more serious than that in adjacent positions. This is because […]