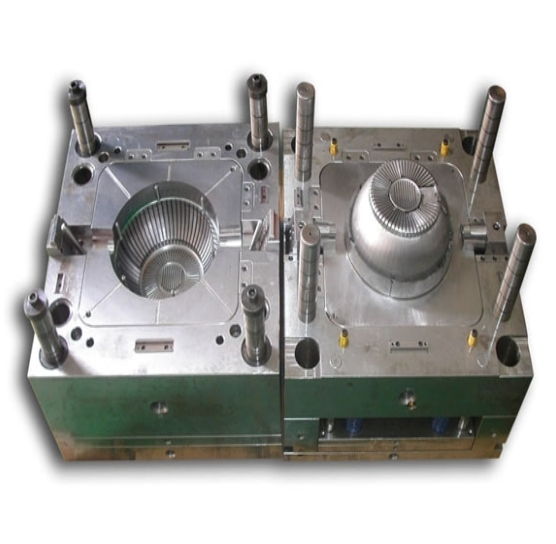

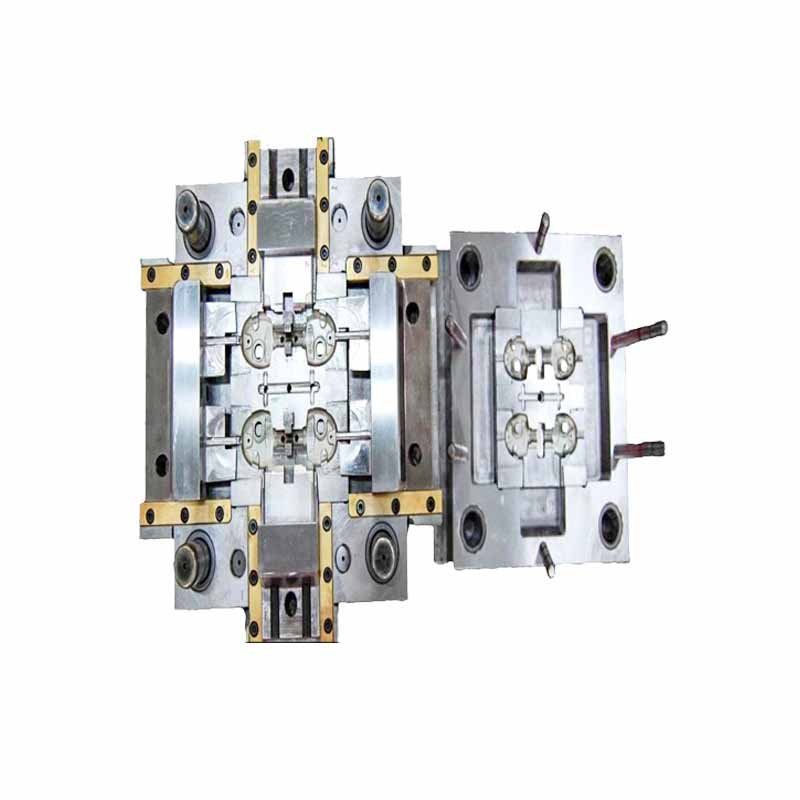

Key structural elements in injection mold design There are several important structural elements to consider when designing an audio plastic molding solution inc. The following is a detailed description of them: 1. Parting surface The parting surface refers to the contact surface between the concave mold and the convex mold when the mold is closed. The […]

Cooperation and precautions for injection mold processing At present, many businesses need to carry out injection mold processing, and the number of companies producing molds on the market is very large. If you plan to cooperate with manufacturers for a long time, you must pay special attention to the other party’s processing capabilities. Whether it […]

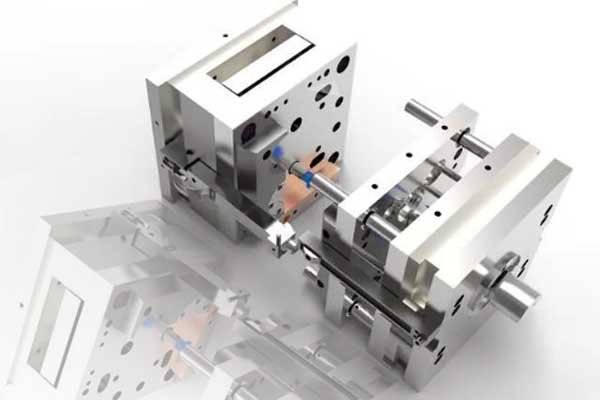

System Engineering of Plastic Injection Mold Processing Plastic mold processing usually requires the help of professional precision equipment to achieve high efficiency and stable product quality. Injection molding is a systematic project, and injection molding equipment is an effective guarantee to ensure a complete set of solutions for precision injection molding products. Excellent injection molding […]

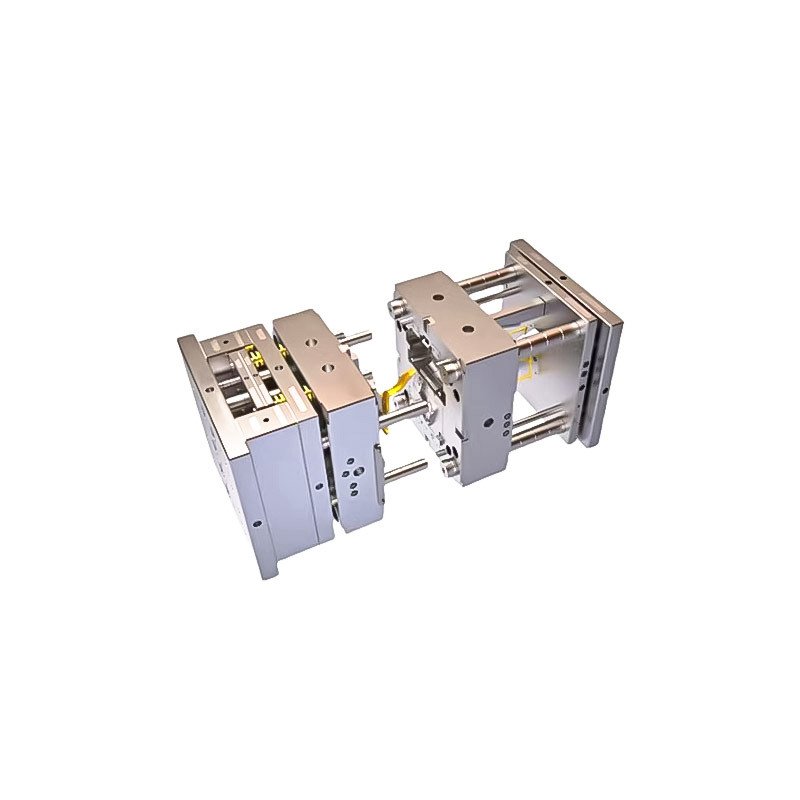

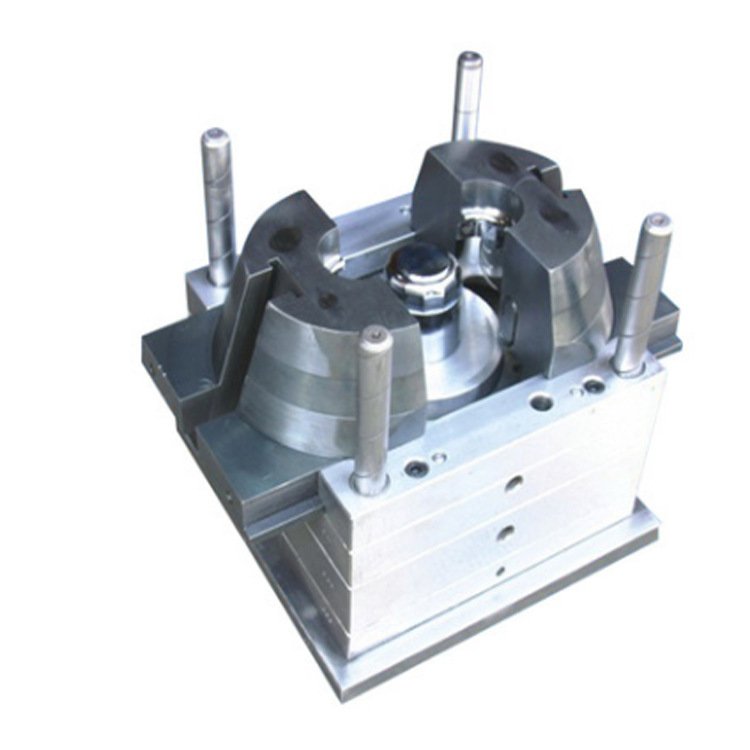

Precision mold design and plastic injection mold manufacturing Before injection molding, mold processing manufacturers need to go through a detailed mold production design process. In recent years, the requirements for precision mold design have become increasingly higher. When designing molds, plastic injection mold manufacturers must use automated design programming and supporting tools to improve the […]

Types and Applications of Injection Molds In production practice, due to the involvement of multiple factors, such as the type of molded plastic, the structural shape and dimensional accuracy of the plastic part, the production batch, the type of injection machine and the injection process conditions, the processing structure of the injection mold is varied. […]

Overview of plastic product processing for medical device shell processing Plastic Contract Manufacturing Company is a method of using thermoplastic plastic sheets as raw materials to manufacture various products under its high elastic economic conditions. The processing of medical device shells is a mature process with relatively strict requirements on materials, mainly including the following […]

Analysis of specific requirements for mold processing The specific requirements for mold processing are very strict, mainly including the following aspects: 1. High precision requirements A mold is usually composed of a die, a punch and a mold frame, and sometimes a multi-piece assembly module may be used. Therefore, the combination of the upper and […]

During the injection molding process of center console, gas lines often appear at the water inlet of PC plastic products, mainly because the injection speed is too fast. To solve this problem, we need to reduce the injection speed and avoid the occurrence of vibration lines and material shortage. 1. Increase the melt temperature First, […]

In custom plastic injection molding services, the performance of the mold directly affects the quality and production efficiency of plastic products. The following are some common mold problems and their solutions. 1. Methods to prevent mold cracks 1. Causes of mold cracks – Insufficient mold rigidity: The mold design is unreasonable, resulting in insufficient overall […]

During the injection molding process of electronic product shells, brittle cracking is a common problem that may be caused by a variety of factors. The following are analysis and improvement suggestions for molds, equipment, raw materials, processes and product design. 1. Mold aspect 1. Gate size: If the gate is too small, consider adjusting the […]