abs plastic molding manufacturers before molding, plastic must be fully dried. When materials containing water enter the mold cavity, silver ribbon-like defects will appear on the surface of the product, and even hydrolysis will occur at high temperatures, causing material degradation. Therefore, the material must be pre-treated before molding so that the material can maintain appropriate […]

Author Archives: sing-oi

PC raw materials have excellent performance, high transparency, good impact toughness, creep resistance, and a wide range of operating temperatures. The process characteristics of PC are: the melt viscosity is less sensitive to shear rate, but more sensitive to temperature, there is no obvious melting point, the melt viscosity is high, the resin is easy […]

Medical injection molding products Because it is required to have good transparency, high wear resistance, and good impact toughness, a lot of work needs to be done on the composition of plastics, the process of the entire injection molding process, equipment, molds, etc., to ensure that these plastics used to replace glass (hereinafter referred to […]

This standard mainly stipulates the inspection and test methods of various plastic products produced by injection molding. It is applicable to the inspection of general HDPE Plastic Injection Molding Manufacturer. This standard is only for routine inspection. Special requirements shall be subject to PARTSPEC. Explanation of common defects 1 Scorch marks (RURNS): material decomposition caused […]

As a cheap and high-performance engineering plastic, PPS is increasingly widely used in custom plastic injection molding. However, its molding characteristics have always been a constraint on its widespread use, and how to improve its burrs is also a problem explored by various molding departments. 1. Introduction to the characteristics of PPS engineering materials PPS, […]

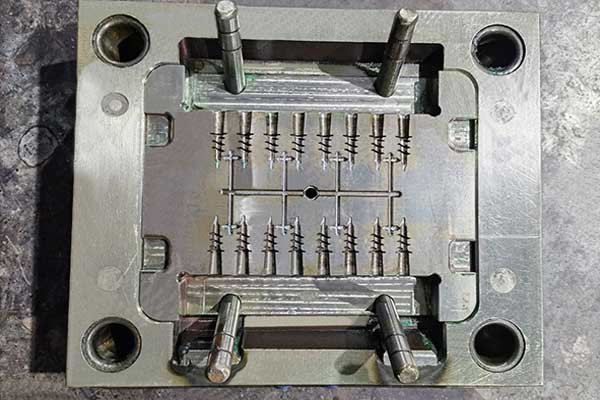

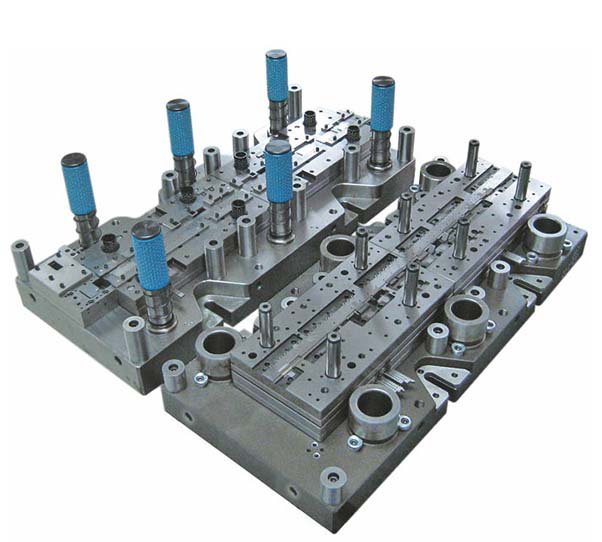

Medical Double-Color Plastic Injection Molding Companies has established standards for mold approval from three aspects: mold structure, plastic part quality, and injection molding process requirements. Based on this, the mold quality is evaluated and scored, hoping to continuously improve the mold quality; ensure that the mold can be put into production normally and produce plastic […]

Analysis of causes and countermeasures of black spots and impurities in center console injection molding. Defects of black spots and impurities are the most important factors that cause scrap rates in normal production processes. They mainly affect the appearance of products and lead to scrapping. Impurities and most black spots are foreign substances and have […]

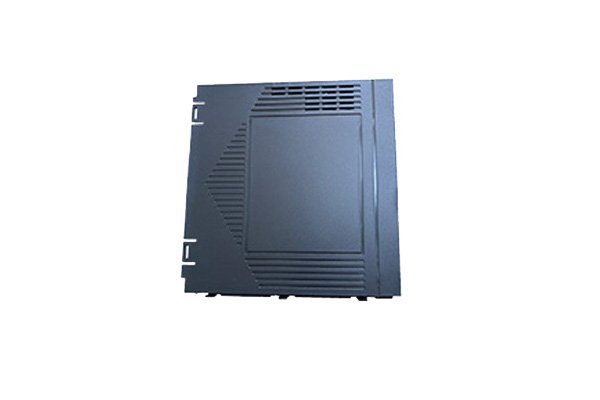

Waves or grooves are common defects in Router Injection Molding Products. Generally, the surface defects caused by the pause of the flow peak due to insufficient injection pressure or reduced injection speed are the result of stress induction of the product. Different surface defect forms have different causes. Exploring these causes and avoiding them is […]

Electronic product shell processing factory after the formula of the filling masterbatch is determined, the granulation process is an important factor that determines the quality of the masterbatch. (1) Heating temperature The heating temperature depends on the softening point or melting temperature of the carrier resin. The higher the softening point or melting temperature of […]

Game controller injection molding manufacturer before molding, plastic must be fully dried. When materials containing water enter the mold cavity, silver ribbon-like defects will appear on the surface of the product, and even hydrolysis will occur at high temperatures, causing material degradation. Therefore, the material must be pre-treated before molding so that the material can […]