Router Injection Molding Products flash is also called overflow, burr, etc. It mostly occurs at the parting position of the mold, such as the parting surface of the dynamic mold and the static mold, the sliding part of the slider, the gap of the insert, the hole of the ejector pin, etc. Flash is largely […]

Author Archives: sing-oi

1. Pigment and dye additives Another way to identify whether plastic parts are genuine is to mix plastic parts with pigments or dyes. Electronic product shell processing factories use spectrometers to analyze the exposed parts and ultraviolet areas. Those pigments or dyes will show unique patterns. Even if counterfeiters use extremely similar colors on their […]

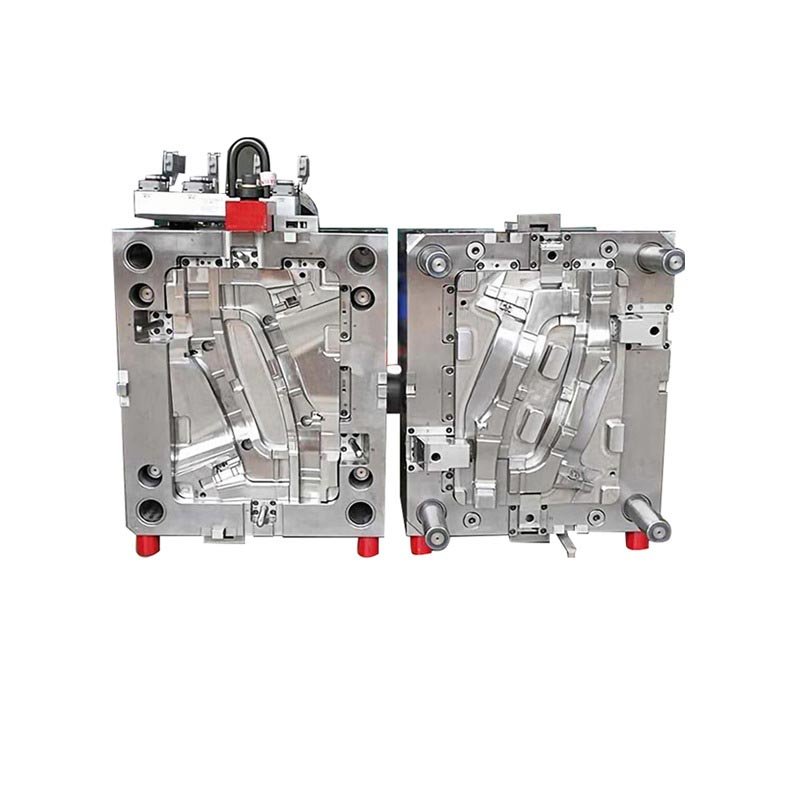

Automotive plastic parts, such as coil skeletons, bases, fuse boxes, lamp holders, blade fuses, central distribution boxes, sheaths, push racks, center console injection molding and outer covers, are mostly injection molded. Since these plastic parts have high design accuracy, conventional injection molding cannot be used for these plastic parts, but precision injection molding technology must […]

The defects and abnormal phenomena of automobile injection molding are ultimately reflected in the quality of injection molded products. The defects of injection molded products can be divided into the following points: (1) Insufficient injection of products; (2) Overflow of products; (3) Dents and bubbles of products; (4) Joint marks of products; (5) Brittle products; […]

Medical Double-Color Plastic Injection Molding Companies and overmolding are two common injection molding processes. Although they both involve multiple molding of two plastic materials, there are differences in specific operation methods and mold design. Two-color mold Two-color mold refers to using the same injection molding machine to mold twice on the same set of molds, […]

1. When HDPE plastic injection molding manufacturers use injection molding technology to produce products, due to the uneven cooling and uneven shrinkage of the plastic in the mold cavity and the unreasonable product structure design, it is easy to cause various defects of the product: shrinkage, weld marks, pores, deformation, burrs, top injuries, and flash. […]

Analysis and solutions to uneven product color in medical injection molding products The main reasons for uneven color of injection molding products and their solutions are as follows: (1) Poor diffusion of colorants, which often causes patterns to appear near the gate. (2) Plastics or colorants have poor thermal stability. To stabilize the color of […]

The influence of custom plastic injection molding gate on parts and the selection of position 1. Requirements for gate position: 1. Appearance requirements (gate marks, weld lines) 2. Product function requirements 3. Mold processing requirements 4. Product warping 5. Is the gate easy to remove 2. Impact on production and function: 1. Flow length determines […]

Overmolding and Insert Molding refers to the molding process of inserting a pre-prepared insert of a different material into the mold and then injecting resin, so that the molten material and the insert are bonded and solidified to form an integrated product. Out-sert molding refers to the process of inserting the injection molded part on […]

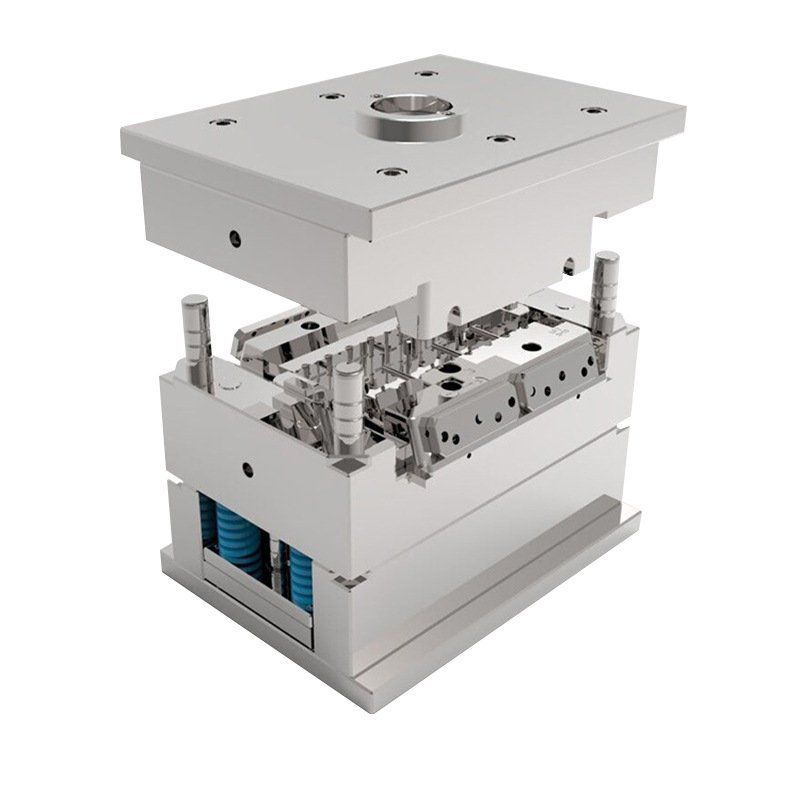

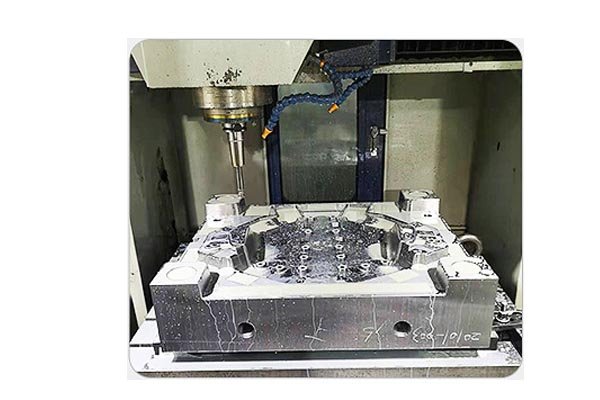

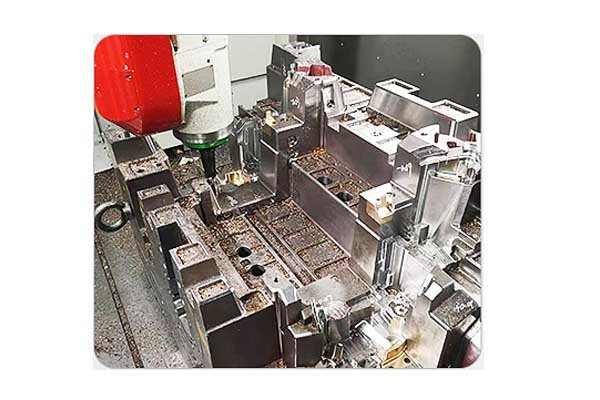

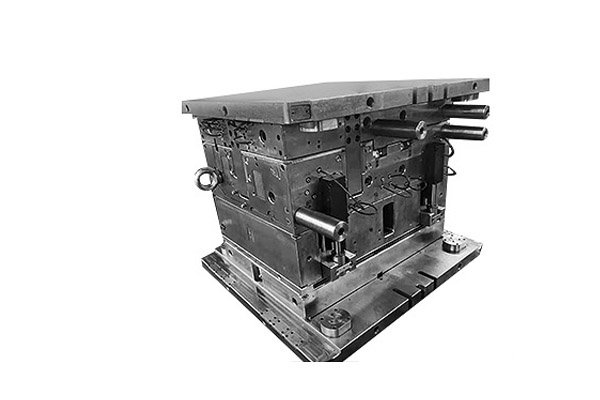

The structural form of Online Injection Molding Service molds and the quality of mold processing directly affect the quality of plastic products and production efficiency. The most common and most frequently occurring mold faults in the production of injection molds and plastic products and their main causes are analyzed and eliminated as follows. 1. Difficulty in […]