Poor surface gloss of AR glasses injection molded products means that the surface of the plastic parts is dim and lacks gloss, and the transparency of transparent products is reduced. There are many reasons for poor gloss, and other injection molding defects may also cause this problem. The following is a defect analysis of poor […]

Author Archives: sing-oi

Router Injection Molding Products poor demolding, also known as die adhesion, occurs when sprues or molded parts stick to the mold, often due to inadequate contact between the injection port and the nozzle arc, incomplete removal of gate material, or abnormal filler conditions. The main runner diameter must be sufficiently large to ensure that the […]

Color change of medical injection molding products, also known as color streaks, refers to the phenomenon that the color of the injection molded product is inconsistent with the standard color. The following is the analysis and troubleshooting methods of color change and color streaks: 1. The quality of the colorant does not meet the requirements […]

Warping refers to the distortion of the shape of an injection-molded product compared to the mold cavity. It is a common defect in plastic products and can be influenced by various factors, including the mold structure, the thermophysical properties of the plastic material, and the conditions and parameters of the injection molding process. As the […]

Silver streaks refer to splash marks formed on the surface of plastic parts, usually caused by the volatilization of air and moisture in the plastic, or the decomposition and burning of foreign plastics after mixing. These marks usually radiate outward from the gate in a fan-shaped manner. Many plastics absorb moisture during storage. If they […]

Flow marks are common surface defects of plastic parts near the gate, which appear as a wavy mark and present a concentric circle centered on the gate. Flow marks are usually caused by uneven temperature distribution of plastic parts during the molding process or too fast plastic solidification. In addition, during the melt flow process, […]

Flash, also known as overflow, burr or burr, usually occurs at the parting position of the mold, such as the parting surface of the dynamic mold and the static mold, the sliding part of the slider, the absolute gap of the insert and the pore of the ejector pin. The generation of flash is largely […]

What is a short shot? Short shot is also called short shot, insufficient filling, and product dissatisfaction, commonly known as short shot, which refers to the partial incomplete phenomenon at the end of the material flow or the partial filling of a part of the multi-cavity in a mold, especially the thin-walled area or the […]

Welding line of overmolding of injection molded parts. The molten plastic in the mold cavity converges in multiple strands due to the holes of the insert, the area of discontinuous flow rate, and the area of interrupted filling material flow. This low-temperature molten material converges in the form of linear welds because it cannot be […]

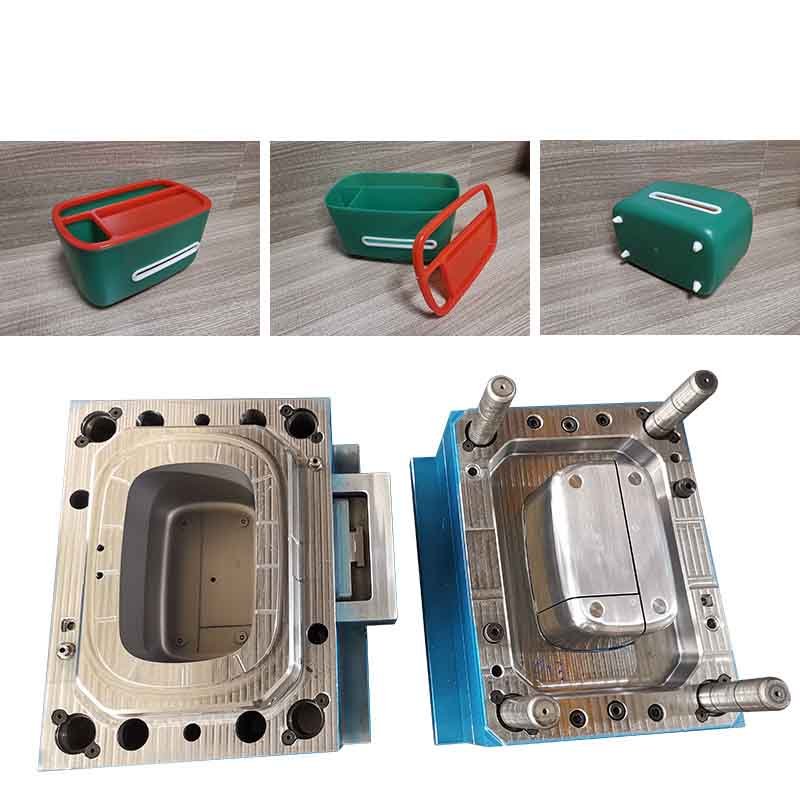

Plastic Injection Molding Services: Your Guide to ABS Plastic Molding Introduction to Plastic Injection Molding What is ABS Plastic? The Importance of Plastic Injection Molding The Process of ABS Plastic Injection Molding Step 1: Designing the Mold Step 2: Preparing the Injection Molding Machine Step 3: Injecting the Plastic Step 4: Cooling and Ejecting the […]